Introduction

In a significant step toward advancing warehouse automation and operational efficiency, DQCRANES successfully exported 20 sets of electric chain hoists to a state-of-the-art logistics center in Mexico. This shipment, consisting of 10 single-speed electric chain hoists and 10 dual speed hoists, was strategically integrated with the facility’s intelligent warehousing system, enabling a remarkable improvement in sorting and handling processes.

Background

The logistics center in Mexico, a pivotal hub for distribution and warehousing operations, was seeking to upgrade its material handling capabilities to keep pace with growing demand and maintain a competitive edge in the market. Recognizing the need for advanced lifting solutions that could streamline operations and improve sorting efficiency, the center’s management team initiated a search for a reliable partner with expertise in electric chain hoist technology.

DQCRANES emerged as the preferred choice due to its extensive experience in designing and manufacturing electric chain hoists, its reputation for delivering robust and reliable equipment, and its ability to offer customized solutions tailored to specific application requirements.

DQCRANES Solution

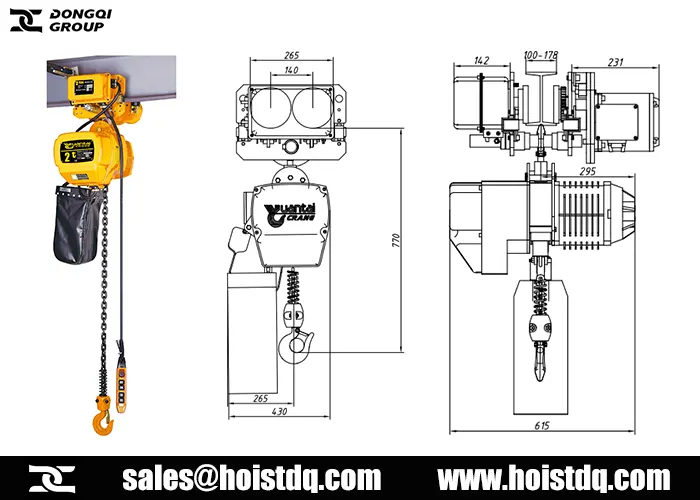

DQCRANES proposed a customized solution involving the deployment of 20 electric chain hoists, designed to integrate with the logistics center’s intelligent warehousing system seamlessly. The equipment was divided into two categories:

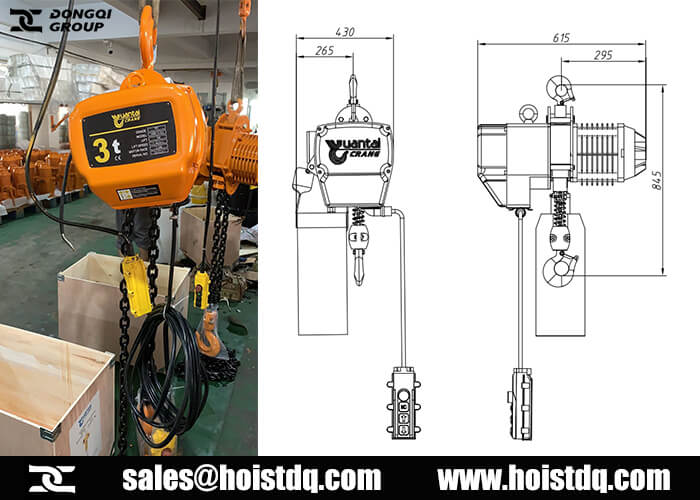

Single-Speed Electric Chain Hoists (10 Units): These single-speed hoists with a lifting capacity of 1 ton were chosen for their reliability and straightforward operation in tasks requiring consistent lifting speeds. They are particularly suited for repetitive handling activities where precision is less critical but efficiency is paramount.

- Lifting capacity: 1 ton and 2 ton

- Lifting height: 6m

- Lifting speed: 3.4m/min, 3.6m/min and 6.8m/min

- Trolley: Motorized trolley

- Power supply: 220V/60Hz/3-phase

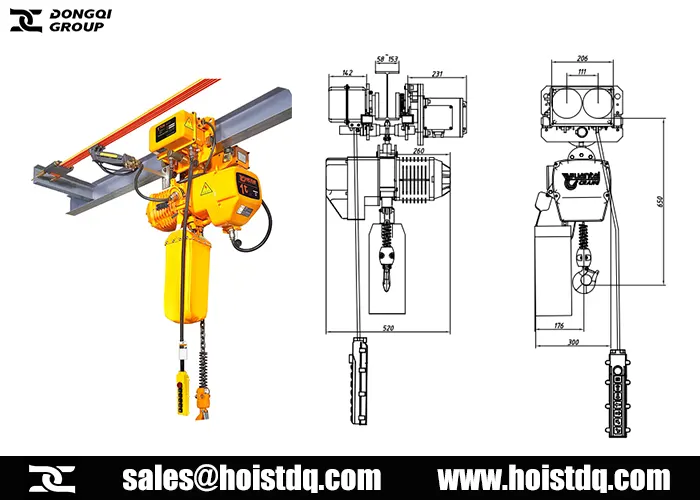

Double-Speed Electric Chain Hoists (10 Units): These dual speed hoists with lifting capacity 1 ton and 2 ton were selected for applications requiring greater flexibility. The dual-speed functionality allows operators to switch between fast lifting speeds for general operations and slower speeds for precise positioning of goods.

- Lifting capacity: 1 ton

- Lifting height: 6m

- Lifting speed: 6.9/2.3m/min

- Trolley: Motorized trolley

- Power supply: 440V/60Hz/3-phase

Both types of electric chain hoists were equipped with advanced safety features, including overload protection, emergency stop functions, and ergonomic controls to enhance operator comfort and reduce the risk of workplace injuries.

Integration with the Intelligent Warehousing System

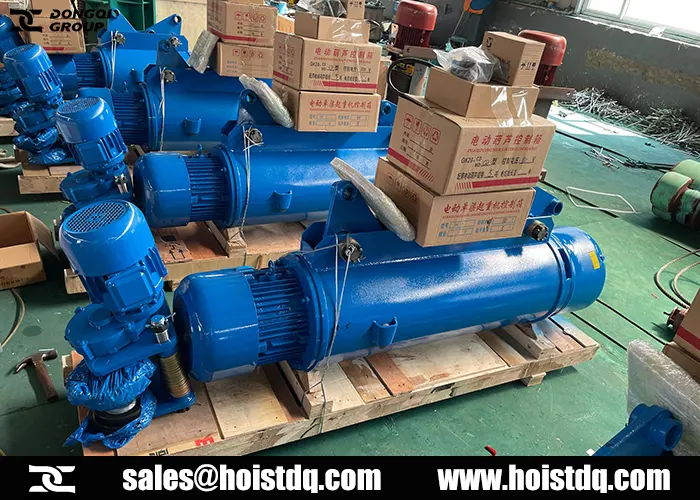

The logistics center’s intelligent warehousing system leverages cutting-edge technologies such as automated guided vehicles, conveyor systems, and real-time inventory tracking software. To maximize the benefits of this system, DQCRANES worked closely with the client’s technical team to ensure seamless integration of the electric chain hoists.

The hoists were installed in key areas of the warehouse, including sorting zones, loading docks, and high-density storage racks. By connecting the hoists to the central control system, operators can now coordinate lifting operations with other automated processes. This synchronization has significantly reduced idle time and improved the overall flow of goods within the facility.

The integration process involved several steps, including:

- Assessment and Planning: A detailed assessment of the logistics center’s layout, operations, and existing infrastructure was conducted to identify the optimal locations for installing the electric chain hoists. A comprehensive plan was then developed outlining the installation process, integration points, and expected outcomes.

- Installation: The electric chain hoists were installed according to the pre-determined plan, with special attention paid to ensuring precise alignment and leveling to prevent any operational issues.

- System Configuration: The hoists were configured to communicate with the warehousing management system using wireless technology. This allowed for real-time monitoring and control of lifting operations, as well as the ability to integrate data for analytical purposes.

- Testing and Commissioning: Rigorous testing was conducted to ensure that the electric chain hoists were functioning correctly and communicating seamlessly with the warehousing system. Adjustments were made as necessary to optimize performance and reliability.

- Training and Support: DQCRANES provided comprehensive training to the logistics center’s staff on the operation and maintenance of the electric chain hoists. Ongoing technical support was also guaranteed to ensure continued optimal performance.

Results and Benefits

- Increased Sorting Efficiency: The combination of high-performance hoists and the intelligent warehousing system has streamlined sorting operations, enabling the center to process more goods in less time.

- Enhanced Precision: The double-speed chain hoists have proven invaluable for handling fragile or high-value items that require careful positioning, reducing the risk of damage during transit.

- Reduced Labor Costs: With automated lifting solutions in place, the need for manual handling has decreased significantly, allowing the center to reallocate its workforce to higher-value tasks.

- Improved Workplace Safety: The hoists’ advanced safety features have minimized accidents and injuries, fostering a safer working environment for employees.

- Scalability: The modular design of the hoists and their compatibility with the intelligent warehousing system provide the flexibility needed to accommodate future expansions or changes in operational requirements.

Client Feedback

The management team at the logistics center expressed their satisfaction with the performance of DQCRANES’ equipment and services. “The electric chain hoists have been a game-changer for our operations,” said the facility’s operations manager. “Not only have we achieved significant efficiency improvements, but we’ve also enhanced our ability to meet customer expectations for faster deliveries.”

Future Collaboration

The client has expressed interest in expanding the system to two additional facilities in Guadalajara and Mexico City in the third quarter of 2025. Amazing!

Conclusion

By combining robust equipment with advanced automation technologies, DQCRANES has helped the logistics center in Mexico achieve new levels of efficiency, precision, and safety. Contact us for smart material handling solutions tailored to your needs!