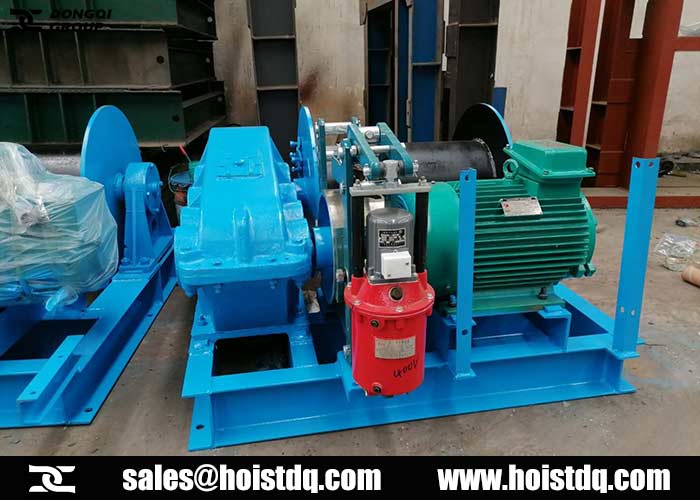

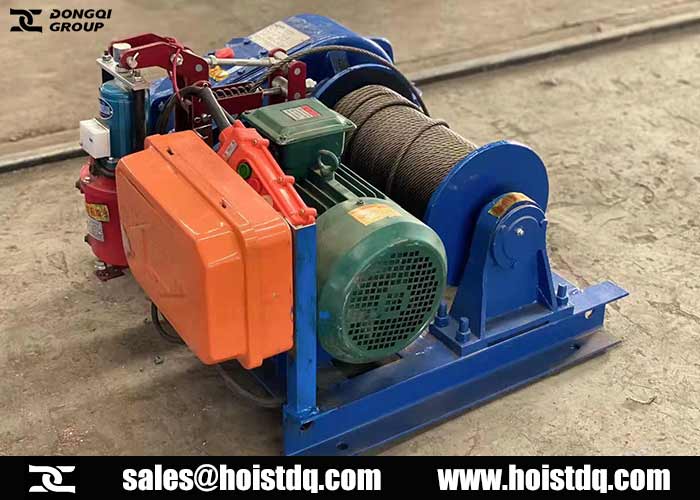

Our Bahrain customer ordered 2 sets JM series 1 ton electric winch for his project. The JM winch will be shipped and reached its destination soon. This slow speed winch is a gear reducer drive winch, with a speed of 5-20m/min. It is suitable for civil construction and installation works of construction and installation companies, mining areas and factories. The winch can lift heavy loads vertically or horizontally, with the features of simple operation, large capacity, and convenient displacement.

JM winch for sale to Bahrain:

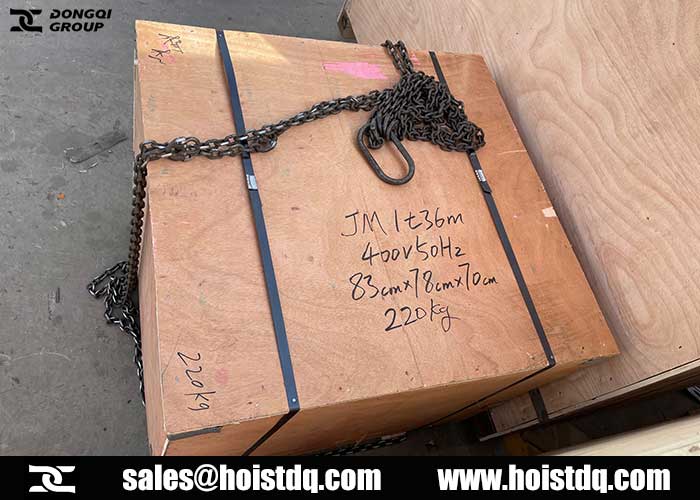

- Lifting capacity: 1 ton

- Rated load: 10KN

- Rope length: 36 meters

- Lifting speed: 12m/min

- Power supply: 400V/50Hz/3 Phase

- Rope diameter: 9.3mm

- Motor power: 2.2KW

- Control method: Control box

- Material : Q235B

- Working temperature ℃ -20 ~+40

- Protection class: IP 54

- Insulation class: F

Electric Winch Design Features:

- JM electric rope winch is powered by an electric motor, is driven by an elastic coupling, a three-stage closed gear reducer, a jaw coupling, and a hydraulic push rod brake.

- JM winch has a large lifting capacity with 1 ton to 500 tons and is widely used in construction.

- JM series electric winch can also be used as supporting equipment for modern electronic control automatic operation lines for material lifting or flat dragging in water conservancy projects, forestry, mines, docks, etc.

Additional Features:

- Slow speed.

- Steadily working.

- Easy to inspect and maintain.

- Convenient to operate and control.

- Heavy duty, Safety and reasonable price.

- High strength component.

- Durable and Reliable.

Safely Operation of Electric Winch:

- The wire ropes on the reel should be arranged neatly. If they are overlapped or slanted, they should be stopped and rearranged. It is strictly forbidden to pull and step on the wire rope with hands or feet during rotation. The hoist wire rope is not allowed to be fully released, and at least three turns should be retained.

- The wire rope is not allowed to be knotted or twisted. If the wire is broken more than 10% within a pitch, it should be replaced.

- The steel wire rope is worn and mechanically damaged during use. Spontaneous combustion corrosion and local damage are inevitable. Protective oil should be painted at intervals.

- During the operation, no one is allowed to cross the wire rope, and the operator is not allowed to leave the hoist after the object is lifted. Objects or cages should be lowered to the ground during rest.

- During the operation, the driver and signalman should maintain good visibility with the hoisted object. The driver and signalman should cooperate closely and obey the unified command of the signal.

- Obey the signal of the commander during the work. If the signal is unknown or may cause an accident, the operation should be suspended, and the operation can be continued after the situation is clarified.

- After the operation is completed, the material tray should be dropped to the ground and the electric box should be closed and locked.

- Overload use is strictly prohibited. That is, the maximum carrying tonnage is exceeded.

- Do not directly hoist high-temperature objects, and protect the objects with edges and corners.

Winch Supplier – JM Winch Manufacturer

JM series slow speed electric winch is mainly for installation and dis-assembly of all kinds of large and super-large concrete and steel structure and mechanical equipment. JM winch from DQCRANES is applicable for the equipment installation for all kinds of bridge, port, wharf engineering project and large factory, such as mining factory equipment installation.

We provide various winch machines according to customer needs to adapt to specific working conditions and improve work efficiency and safety. Contact us and Get a quote on an electric winch today!