Introduction

As a leading manufacturer of electric chain hoists and material handling solutions, DQCRANES is committed to providing high-quality products and excellent service to our clients worldwide. Our client is a newly established manufacturing facility in Morocco, specializing in the production of heavy machinery and equipment. With a focus on efficiency and safety, the client required reliable material handling equipment to streamline their production processes and ensure the smooth movement of heavy loads within their facility.

Requirements

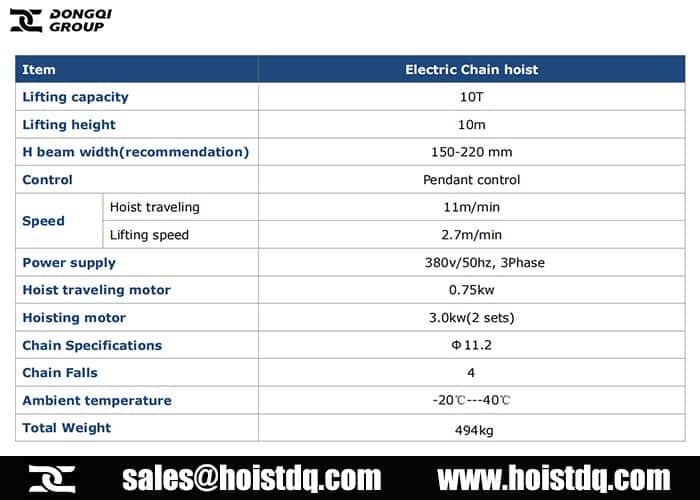

The client’s primary requirement was a 10 ton electric chain hoist that could handle heavy loads with precision and safety. They needed a solution to integrate seamlessly into their manufacturing operations while meeting safety standards.

The client contacted DQCRANES to get a suitable material handling solution. With a reputation for delivering custom-engineered solutions and exceptional customer service, DQCRANES was well-positioned to meet the client’s needs.

Solution

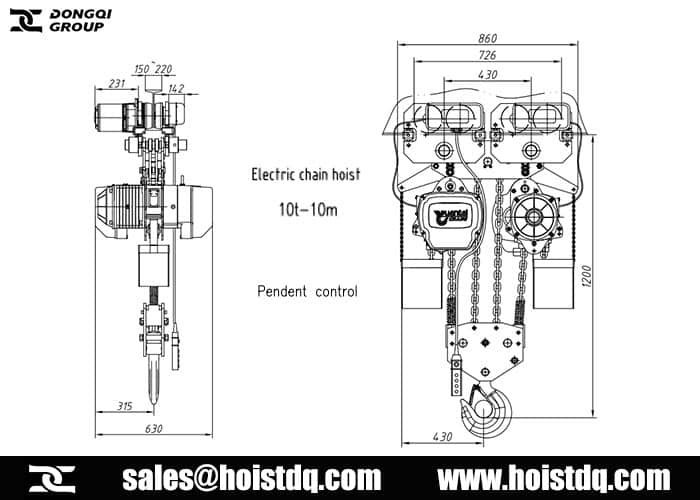

Our team of experienced engineers and technical experts carefully assessed the client’s requirements and facility layout to design a tailored solution. After thorough analysis and consultation with the client, we proposed a 10 ton electric chain hoist with motorized trolley that would provide the necessary lifting capacity and maneuverability required for their operations.

Design Details:

Design Features:

- Motor shell: It is made of light aluminum alloy shell, light but hard. The cooling fin is especially designed to ensure quick heat dissipation with the rate up to 40% and continuous service. The integral enclosed structure applies to places like chemical plants and electroplate factories.

- Motor: Special designed for the electric chain hoist. Maintenance free. Insulation grade F. Protection class IP54. Side magnetic braking system inside.

- Gearbox: Forged medium carbon steel, good toughness, strong impact resistance& bearing capacity, made by generating method, gear grinding processing, and high precision degree.

- Motorized trolley: High strength low alloy steel structure, with electric motor and high-wearing feature wheels, compact and easy to install.

- Chain: The chain shall adopt the imported ultra-heat treatable aluminum alloy chain. It can be safely used in power environments such as rain, seawater, and chemicals.

- Chain container: High wear resistance nylon material, store the lifting chain and prevent the chain from getting entangled with the main card or the chain when the chain is free to slide.

- Hook: It is hot forging with perfect strength that is hard to break. The operation safety of the lower hook is ensured by its 360-degree rotation and safety flap.

- Overload Limit switch: The limit switch device is installed where the weight is lifted on and off to make the motor stop automatically to prohibit the chains from exceeding safety.

- Pendant control: 4 Pts, left and right, up and down; with emergency stop.

Benefits

- Increased productivity: The 10 ton lifting capacity and motorized trolley system enable efficient handling of heavy loads, accelerating production processes.

- Improved safety: Safety features like limit switches and overload protection minimize operational risks.

- Enhanced operator comfort: Pendant or radio remote control allows for safe and ergonomic operation from a distance.

- Reduced downtime: Durable construction and readily available after-sales support from DQCRANES minimize downtime and maintenance needs.

Why Choose Electric Chain Hoist from DQCRANES?

DQCRANES offers a comprehensive range of electric chain hoists for sale to meet the diverse needs of our clients. Our electric trolley hoists are engineered for durability, reliability, and precision, backed by our commitment to quality and customer satisfaction. With a focus on innovation and continuous improvement, DQCRANES delivers cutting-edge solutions that enhance operational efficiency and safety.

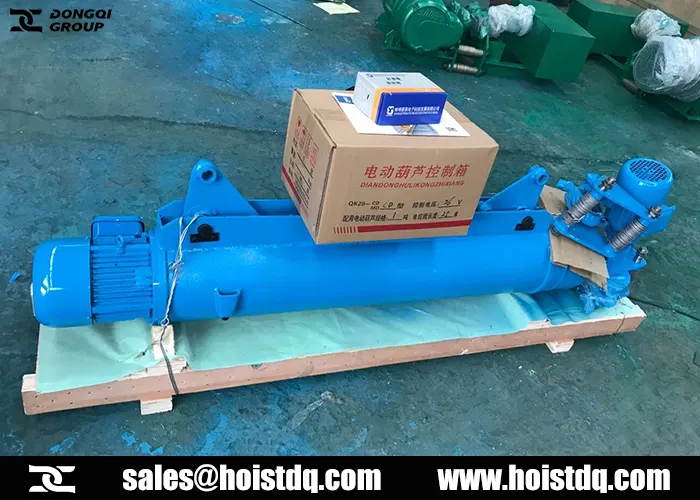

Production and Delivery

Once the design was approved by the client, our production team commenced the manufacturing process using high-quality materials and advanced manufacturing techniques. Stringent quality control measures were implemented throughout the production process to ensure that the final product met our strict quality standards. Upon completion, the 10 ton electric trolley hoist was carefully packaged and delivered to the client’s facility in Morocco.

Feedback

Following the installation and commissioning of the electric chain hoist with trolley, our client expressed their satisfaction with the performance and reliability of the equipment. They were particularly impressed by its smooth operation, precise controls, and robust construction, which exceeded their expectations. The seamless integration of the hoist into their manufacturing processes contributed to improved efficiency and productivity within their facility.

Contact DQCRANES

For a free consultation and a customized quote for your specific needs, contact DQCRANES today. Our team of experts will be happy to discuss your requirements and recommend a suitable electric chain hoist for your application.