At DQCRANES, our mission is to provide world-class lifting solutions tailored to meet the unique needs of industries worldwide. Recently, we had the privilege of designing, manufacturing, and exporting a European standard 10-ton monorail hoist to a prominent construction site in Mexico. This project exemplifies our commitment to engineering excellence, customer satisfaction, and global collaboration.

Challenges

The construction industry in Mexico is rapidly expanding, with increasing demand for advanced lifting equipment that ensures efficiency and safety. Our client – a leading construction company—required a robust and reliable hoist to handle heavy materials at their site. The key challenges included:

- High Lifting Capacity: The hoist needed to handle loads up to 10 tons with precision and stability.

- Compliance with FEM Standards: The client emphasized the importance of adhering to strict safety and quality standards.

- Adaptability to Local Conditions: The equipment had to perform reliably under Mexico’s environmental conditions, including high temperatures and dust exposure.

- Ease of Installation and Operation: Given the tight project timeline, the hoist must be easy to install and user-friendly for operators.

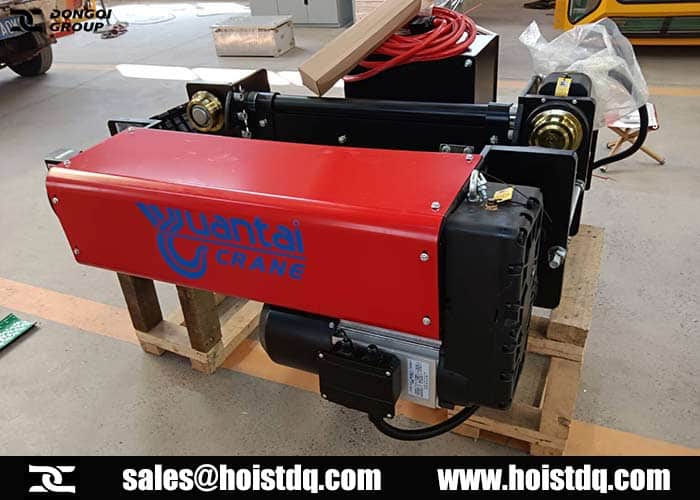

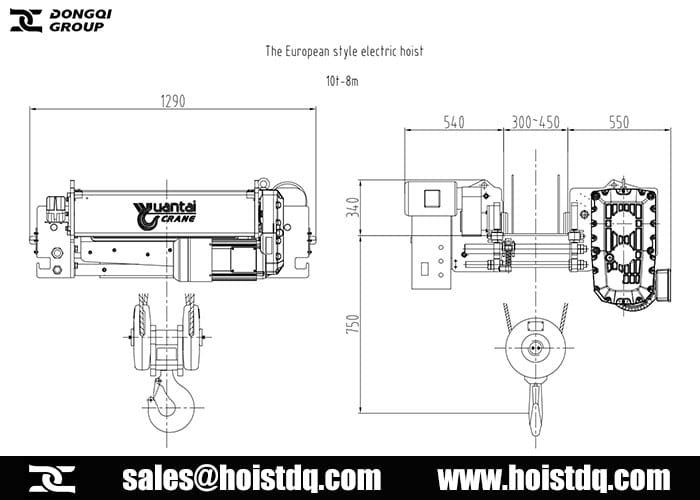

10 Ton Monorail Hoist Design

Our engineer began by designing the monorail hoist using advanced 3D modeling software. Every component was meticulously planned to ensure optimal performance, durability, and compliance with European standards. Key features of the design included:

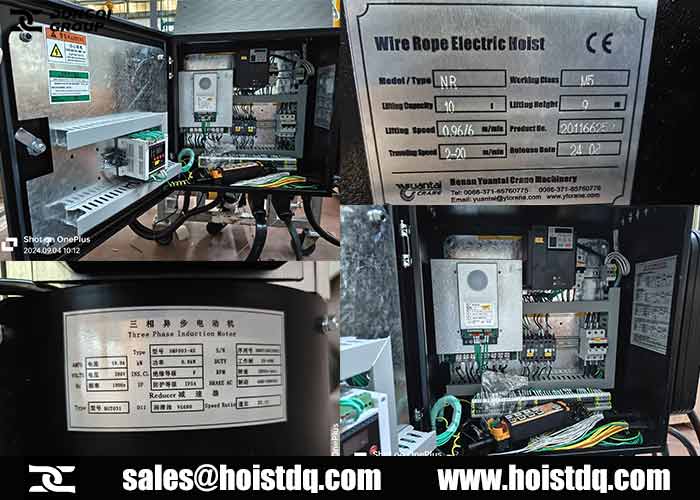

| Lifting capacity | ton | 10 |

| Lifting height | m | 8 |

| Lifting speed | m/min | 0.96/6 STEPLESS |

| Traveling speed | m/min | 2.0~20 STEPLESS |

| Power supply | V/Hz | 440/60/3-phase |

| Control method | / | Remote control |

| Working duty | / | FEM 2m (M5) |

| Working site | / | Indoor |

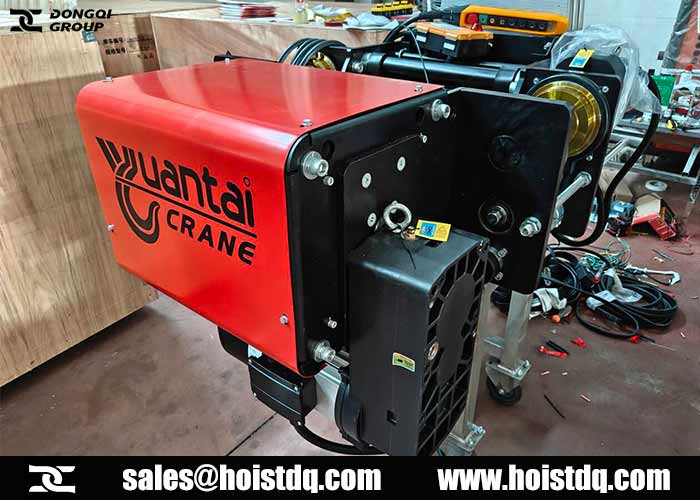

- Hoist mechanism: Inverter traveling speed and Double lifting speed. Reducer, drum, motors. Protection class IP54.

- Main frame: Main structure material high strength Q235B, with the traveling system. Rational and compact design, Increase the hoist lifting height; make full use of the vertical space.

- Lifting motor: Squirrel Cage and Frequency Conversion Hoist Motor. Protection class IP54, Insulation class F; Enclosed type with Splash Lubrication. Electromagnetic disc type brake system. Maintenance free.

- Traveling motor: Three-in-one motor (Motor, reducer, and gearbox together as one), Maintenance free.

- Electric trolley: Alloy gear and wheels, 125% testing load of the rated capacity.

- Wire rope: Rope structure 6×36SW, steel core.

- Hook: Four rope wire hook forged type with safety latch.

- Remote control: Radio frequency control, Safe and reliable.

Safety Features:

Equipped with overload protection, emergency stop systems, and fail-safe braking mechanisms, the hoist prioritized operator safety.

Our team also incorporated energy-efficient technology to minimize power consumption without compromising performance.

Production and Delivery

Exported to Mexico

DQCRANES prepared all necessary export documentation, including:

- Commercial invoice

- Packing list

- Bill of lading

- Certificate of origin

- Export license (if required)

- Compliance certificates (e.g., CE marking, if required)

Installation and Commissioning

Upon arrival in Mexico, we coordinated with the local service team to ensure a seamless installation process, we provided detailed manuals and online installation support. Our experienced technicians supervised the assembly and commissioning of the hoist by video, ensuring it was fully operational within the client’s timeline.

During the commissioning phase, we conducted training sessions for the client’s operators. These sessions covered:

- Safe operation procedures

- Maintenance guidelines

- Troubleshooting techniques

This hands-on training empowered the client’s team to maximize the efficiency and lifespan of the equipment.

Conclusion

The successful delivery of this European standard 10-ton monorail hoist to Mexico underscores DQCRANES’ ability to meet complex industrial challenges on a global scale. By combining innovative engineering, rigorous quality control, and exceptional customer service, we continue to set new benchmarks in the lifting equipment industry.

Whether you’re in construction, manufacturing, or any other sector requiring advanced lifting solutions, DQCRANES is your partner for success. Contact us today to discuss how we can help elevate your operations!