This is an old customer in New Zealand, Europe. Mr. Paul is in the machining industry. He has purchased portable gantry crane, wall mounted jib crane already. This is the third time he choose us for chain hoists supply, and he need 20 units of manual chain hoists to apply in his workshop for maintenance.

Dongqi Hand Chain Hoists combine a rugged exterior shell with machined interior components to handle your most demanding lifting operations. An efficient drive train minimizes manual effort, while a double enclosed brake cover, standard slip clutch and double pawl springs enhance performance and reliability.

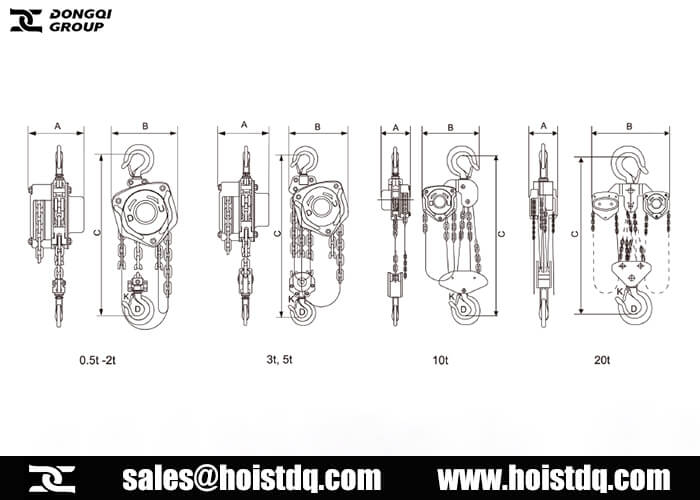

Manual chain hoist for sale:

- Lifting capacity: 10 ton

- Lifting height: 3m

- Working class: A3

Detailed drawing as follow:

Why choose hand chain hoist for lifting application:

- Excellent performance and easy maintenance combined with small volume and light weight construction makes this chain hoist a preferred tool.

- Our manual chain hoists are specially designed to lift, pull and drag loads in heavy duty construction and industrial areas.

- Both in confined spaces and in the open air.

- Only grade 80 high quality heat treated steel load chain is used to ensure reliable operation and long life service.

- Chain hoists comes complete with hand chain, load chain, safety hooks top and bottom, durable finish and a certificate of load testing.

How does a manual chain hoist work?

- Chain hoist uses a mechanical advantage to transform small force over a long distance to large force over a short distance, this is possible by using multiple larger and smaller gears in the chain hoist mechanism.

- To lift a load, chain hoist operator needs to pull down the hand chain, this turns the cog and axle which goes trough the lifting mechanism.

- Inside the lifting mechanism are multiple gears which increase the mechanical work applied when pulling the hand chain for dozen times using gear ratio, allowing to easily lift loads with multiple ton capacity.

- So when the hand chain is pulled, the cog which is rotated by the hand chain turns the drive shaft and gears which turn the load chain sprocket, this also rotates the load chain that is looped over the load chain sprocket and lifts a load.

- At the end of the lifting chain is a grab hook, which allows to easily attach and detach a load.

- Also, most chain hoist lifting mechanisms have a ratchet or braking system that prevents the load from slipping back, but allows to lower a load by pulling the other side of the hand chain.

Advantages for using manual chain hoists for lifting:

- Don’t need electricity, oil or other additional resources to work.

- Cheaper than electric or hydraulic hoists.

- Simple to use and easy to repair and maintain.

Manual chain blocks lift loads to new heights!

Chain blocks are a manual hoist that is very flexible and efficient, can meet a great solution for manual handling and lifting requirements, including applications within the assembly line, at a workstation, job site or workshop, also used in rigging, maintenance, construction, automotive, general manufacturing, mining, and oil applications.

Require further information? Contact us today or continue browsing our wide range of lifting equipment.