Project Overview

- Client: A leading automotive parts manufacturer in Toronto, Ontario, specializing in precision components for electric vehicles (EVs).

- Requirement: Upgrade legacy overhead cranes to enhance production line flexibility, improve safety, and meet stringent European efficiency standards.

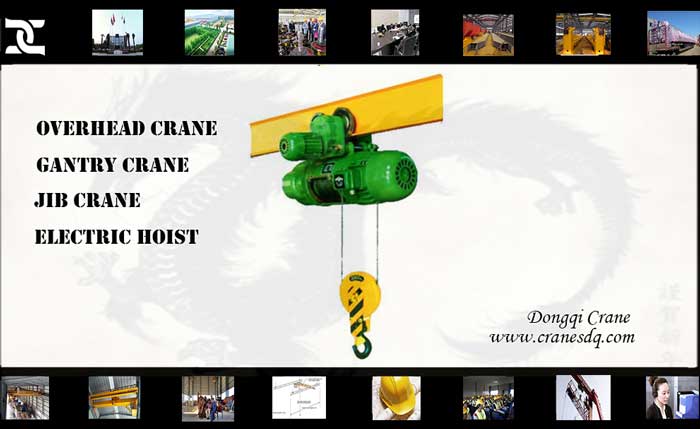

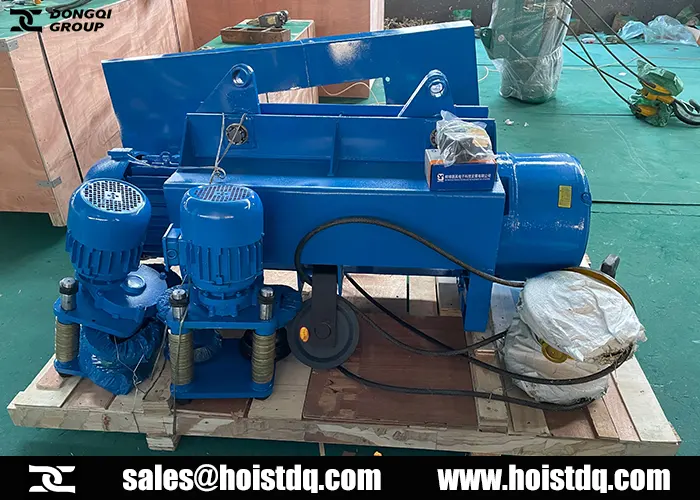

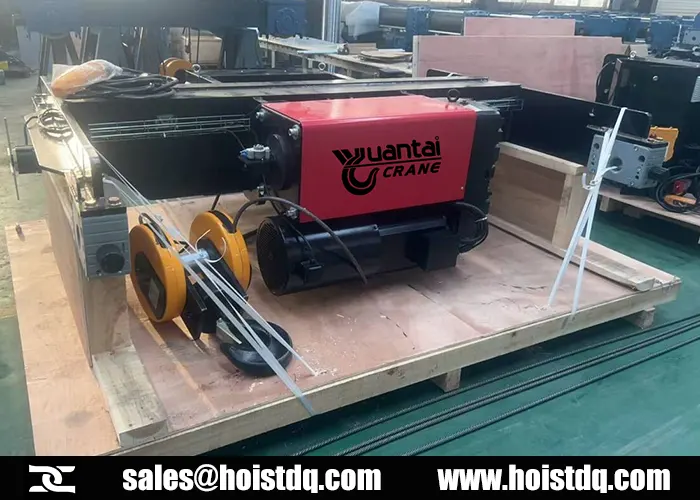

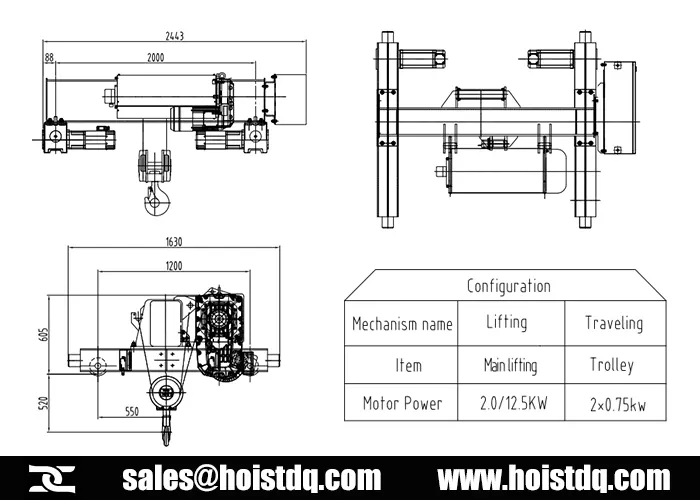

- Solution: DQCRANES designed and delivered a 16-ton double girder European-style wire rope hoist with dual lifting speeds (0.45/2.7 m/min) and a lifting height of 6 meters, tailored for high-precision assembly tasks.

Client Background & Challenges

Industry:

- Automotive manufacturing (EV battery modules and chassis components).

Pain Points:

- Existing electric rope hoists lacked precision control, causing alignment issues during assembly.

- Frequent downtime due to outdated equipment maintenance.

- Space constraints in the factory required a compact, low-headroom design.

Technical Specifications & Customization

DQCRANES proposed a European-standard double girder hoist with the following features:

| Parameter | Specification |

| Capacity | 16 tons (dual-speed lifting) |

| Lifting Height | 6 meters |

| Track Gauge | 2m |

| Lifting Speed | 0.45 m/min (precision mode), 2.7 m/min (standard mode) |

| Traveling Speed | 2.0~20 m/min |

| Motor | Three-in-one motor, Frequency converting control |

| Insulation grade | F |

| Protection class | IP54 |

| Safety Features | Overload protection, emergency stop, limit switches, etc |

| Structural Design | Double girder configuration with Euro-spec trolley |

| Working Class | FEM 2M (equivalent to ISO M5) |

| Power Supply | 220V/50Hz/3phase |

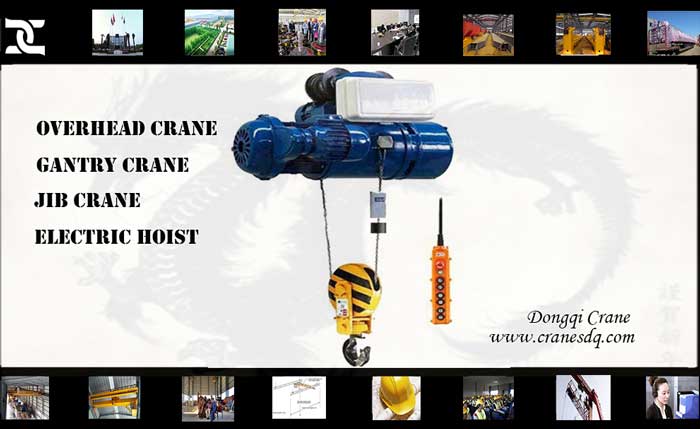

| Control Method | Remote control |

QDX 16 Ton FEM Hoist Design Solutions

A. Dual-Speed Precision Control

- Challenge: The client required precise positioning (±2mm accuracy) for EV battery module assembly.

Solution:

- Low-speed mode (0.45 m/min): Enabled micro-adjustments during component alignment.

- High-speed mode (2.7 m/min): Accelerated material transfer between workstations.

- Integrated anti-sway technology minimizes load oscillation during movement.

B. Space Optimization

- Challenge: Limited vertical clearance in the facility.

Solution:

- The low-headroom trolley design saved 15% vertical space compared to traditional hoists.

- The double girder structure provided superior stability without increasing the footprint.

C. Energy Efficiency

- High-class Motor + VFD: Reduced energy consumption by 25% versus hydraulic systems.

- Electromagnetic disc type brake system: Captured kinetic energy during deceleration, making the lifting smooth and stable.

D. Compliance

- Certifications: CE marking (EU) and ISO 9001/45001.

- Local Adaptation: Collaborated with Toronto-based engineers to customize cold-weather components (e.g., frost-resistant wire ropes).

electric hoist Safe Operations

Pre-Operation Safety Checks

A. Equipment Inspection

- Wire Rope: Check for fraying, kinks, or broken strands (replace if damage exceeds 10% of rope diameter).

- Hook: Inspect for cracks, deformation, or wear on the latch.

- Brakes: Test emergency and service brakes for responsiveness.

- Limit Switches: Verify upper/lower travel limits and overload protection systems.

- Electrical Components: Look for exposed wires, loose connections, or corrosion.

B. Load Capacity Compliance

- Never exceed the Working Load Limit (WLL) marked on the hoist.

- For tandem lifts (multiple hoists), ensure load distribution is balanced and certified by an engineer.

C. Environmental Readiness

- Temperature: Use hoists rated for ambient conditions (e.g., -20°C to +40°C for standard models).

- Hazardous Areas: In explosive atmospheres (e.g., chemical plants), use ATEX-certified hoists with anti-spark components.

Safe Operation Procedures

A. Lifting and Moving Loads

- Centering the Load: Ensure the load is centered under the hook to prevent swinging.

- Smooth Acceleration/Deceleration: Use variable frequency drives (VFDs) to avoid sudden jerks.

- Anti-Sway Systems: Activate technology (if equipped) to minimize load oscillation.

B. Speed and Control

Dual-Speed Modes:

- Low Speed (0.1–1 m/min): For precise positioning (e.g., aligning machinery).

- High Speed (5–20 m/min): For general material handling.

- Remote Controls: Maintain a safe distance from the load during operation.

C. Prohibited Actions

- Do NOT lift loads over personnel.

- Avoid side-pulling or dragging loads horizontally.

- Never use the hoist to lift people.

Post-Operation Safety

- Parking: Secure the hoist in a designated area, raise the hook to mid-height, and power off.

- Lockout/Tagout (LOTO): Isolate energy sources during maintenance.

- Post-Use Inspection: Document any issues (e.g., unusual noises, brake slippage).

Types of Wire Ropes Hoists in Canada

How to Purchase an Electric Hoist from DQCRANES

Step 1: Assess Your Requirements

- Application: Define the hoist’s purpose (e.g., automotive assembly, warehouse logistics, mining).

- Load Capacity: Confirm the maximum weight to be lifted.

- Lifting Height: Specify vertical travel distance.

- Duty Cycle: Determine usage frequency.

- Environmental Conditions: Consider temperature, humidity, and hazardous areas (e.g., explosion-proof areas).

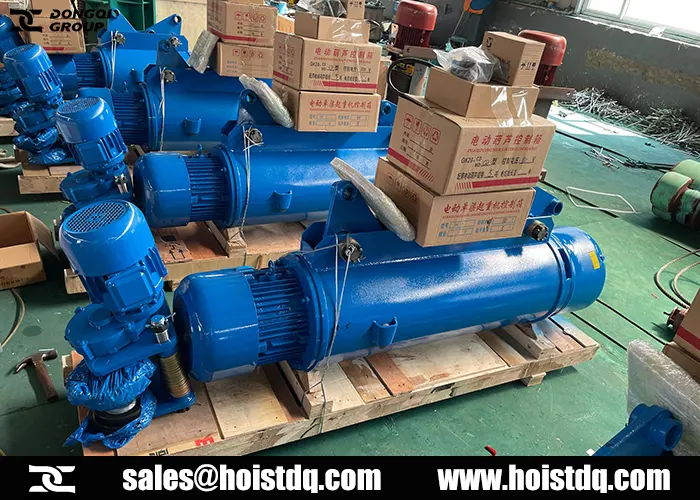

Step 2: Contact DQCRANES

- Website/Email: Visit DQCRANES’ official website – www.hoistdq.com or email sales@hoistdq.com.

- Request a Quote (RFQ): Provide technical specifications and site conditions for a tailored proposal.

Step 3: Review Technical Proposal

DQCRANES will typically provide:

- 3D CAD drawings for hoist and runway system, price list.

- Compliance Details: CE/ISO certification and safety features.

- Customization Options: Dual-speed motors, Single phase or three phase hoists.

Step 4: Finalize Logistics and Installation

- Shipping: DQCRANES ships from China factories (lead time 5–10 weeks), or faster delivery is available.

- Installation: Choose between:

- DQCRANES’ remote guide for simple setups or on-site technicians (for complex setups).

- Local contractors (pre-vetted by DQCRANES).

- Testing: On-site load testing and safety inspections post-installation.

Step 5: Payment and Financing

- Payment Terms: 100% T/T before production for lighter tones. Typically 50% upfront, 50% before delivery for heavier tones. (Other types are optional for the client’s needs.)

Step 6: Training and After-Sales Support

- Operator Training: Remote or On-site sessions for safe operation and controls.

- Warranty: Standard 12-month warranty (extendable).

- Service Network: Access to DQCRANES’ service center for spare parts and repairs.

Conclusion

Purchasing an electric hoist from DQCRANES in Canada can secure safety, efficiency, and long-term value. For any questions or a free quote, welcome to contact us at +86-188-3818-4113 directly.