Background

Our client in Mauritius is a leading industrial manufacturing company with a focus on heavy machinery production. With an extensive range of machinery and equipment operating on their premises, the client recognized the need for a reliable and efficient lifting solution to facilitate regular maintenance and repairs. After thoroughly consulting with our other customer in Mauritius, they contacted us – DQCRANES for a customized monorail hoist solution that would align with their specific operational requirements.

Requirements

The client’s machinery maintenance operations involved the lifting and positioning heavy components weighing up to 3 tons. They required a monorail hoist with European standards that could seamlessly integrate into their existing infrastructure, and provide precise and stable lifting capabilities. Furthermore, the client emphasized the importance of durability, ease of maintenance, and overall cost-effectiveness in their selection criteria.

Solution

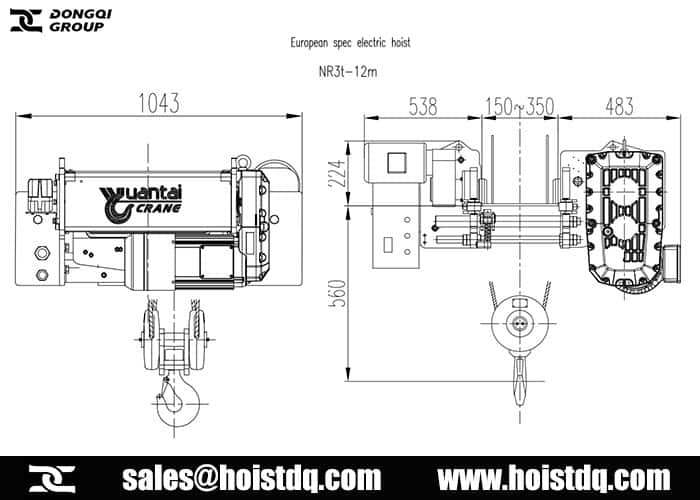

Upon receiving the client’s detailed requirements, DQCRANES’ engineers and technical experts conducted a comprehensive assessment of the client’s facility and operational needs. Taking into account the load capacity, lifting height, and environmental factors, DQCRANES proposed a tailored design solution featuring a European standard 3 ton monorail hoist.

Design details:

- Lifting capacity: 3 ton

- Lifting height: 12m

- Lifting speed: 0.96/6 m/min

- Traveling speed: 2~20 m/min STEPLESS

- Lifting motor: 0.45/3.2 kW

- Trolley motor: 0.4kW

- Power supply: 380V/50Hz/3Phase

- Working class: FEM 2m (M5)

- Control method: Pendent control

- Working site: Indoors

- Working temperature: -10°C~+40°C

Design features:

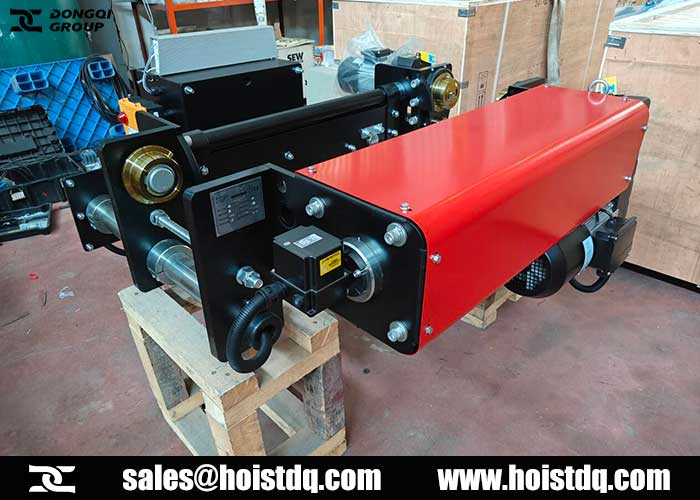

- High-strength steel structure for enhanced durability and load-bearing capacity

- Precision-engineered hoisting mechanism for smooth and precise lifting operations

- Advanced safety features including overload protection, emergency stop functionality, and anti-sway technology

- Compact design for seamless integration into the client’s existing monorail system

- Low-maintenance components to minimize downtime and maintenance costs

- Compliance with European standards for assured quality and safety

Why Choose European Standard Monorail Hoist?

European standard monorail hoists offer several benefits for machinery maintenance. These hoists are designed to provide efficient and safe lifting solutions for industrial applications, making them an ideal choice for maintenance tasks in manufacturing facilities, warehouses, and other industrial settings.

- Superior lifting capacity. These monorail hoists with capacities from 1 ton to 80 tons, are capable of lifting heavy machinery and equipment with ease, allowing maintenance personnel to safely and efficiently perform tasks such as equipment repairs, inspections, and installations. This high lifting capacity helps to minimize downtime and improve overall productivity in industrial environments.

- Precision and control. These NR series electric hoists are equipped with advanced control systems that allow for smooth and precise movement, making it easier for maintenance personnel to position machinery accurately during maintenance tasks. This level of control not only enhances safety but also contributes to the quality and efficiency of maintenance operations.

- Durability and reliability. These FEM hoists are built to withstand the rigors of industrial use, featuring robust construction and high-quality components that ensure long-term performance. This reliability is crucial for maintaining a safe and productive work environment, as it minimizes the risk of equipment failure during maintenance activities.

- Safety in mind. These hoists are equipped with a range of safety features, such as overload protection, emergency stop functions, and redundant braking systems, to ensure the highest level of safety for maintenance personnel and the surrounding work environment. By prioritizing safety, these hoists help to mitigate the risks associated with machinery maintenance tasks.

- High efficiency. European standard monorail hoists’ streamlined design and smooth operation enable maintenance personnel to complete tasks more quickly and with greater ease, ultimately reducing the time and labor required for maintenance activities. This efficiency translates to cost savings and improved operational performance for industrial facilities.

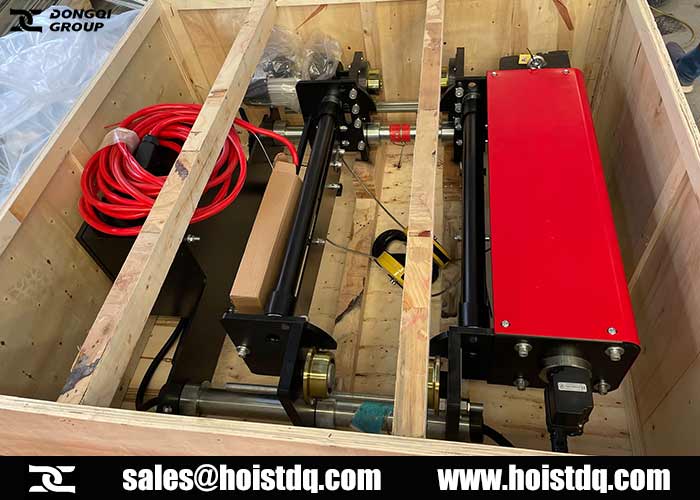

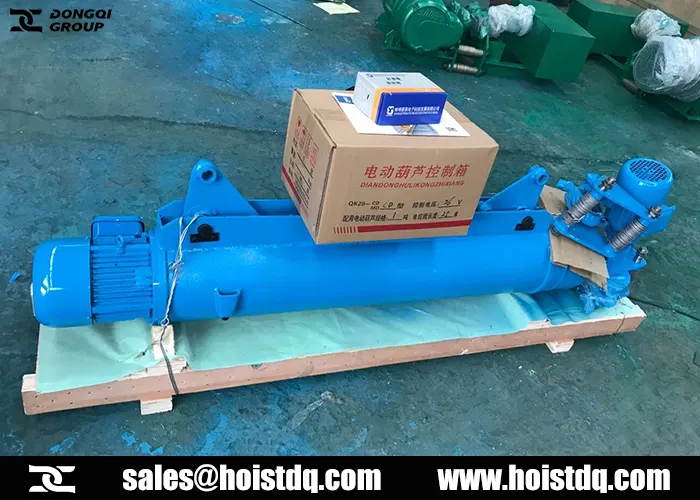

Production and Delivery

Following the design approval, the client finished the payment. DQCRANES initiated the production of the European standard 3 ton monorail hoist and adhered to strict quality control measures and industry best practices to ensure the highest standards of craftsmanship and performance. Once completed, the monorail hoist underwent rigorous testing procedures to validate its functionality, safety features, and compliance with European standards.

Upon successful testing, the European standard 3 ton monorail hoist was shipped to Mauritius. DQCRANES’ team coordinated the installation and commissioning process on-site, providing comprehensive training to the client’s personnel on the operation, maintenance, and safety protocols associated with the monorail hoist.

Get electric hoist Price!

Explore our high-quality European standard monorail hoist, perfect for various lifting applications in Mauritius. Designed for durability and efficiency, this 3 ton hoist ensures safety and reliability in your operations. Contact DQCRANES today for competitive pricing and expert support!