Introduction

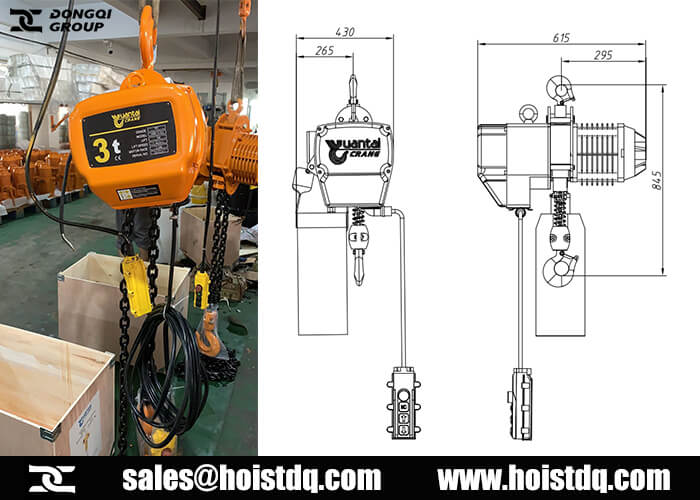

In the automotive repair industry, the need for efficient and reliable lifting equipment is paramount. Electric chain hoists have emerged as a popular choice to meet this demand due to their versatility, ease of use, and cost-effectiveness. In this case study, we will explore how DQCRANES provided a tailored solution for an automotive repair shop in the Dominican Republic, enhancing their operations with a 3 ton single phase electric chain hoist.

Client’s Background

The client, a prominent automotive repair shop in the Dominican Republic, specializes in servicing a wide range of vehicles including cars, trucks, and commercial vehicles. With a commitment to delivering high-quality repairs and maintenance services, the client sought to upgrade their lifting equipment to improve efficiency and safety within their facility.

Client’s Requirements

The client’s primary requirement was to procure a single phase electric chain hoist capable of lifting 3 tons, suitable for their diverse range of vehicles. Additionally, they emphasized the importance of a reliable and durable solution that could withstand the demands of their daily operations. As a reputable provider of lifting equipment, DQCRANES was approached to deliver a customized solution that aligned with the client’s specific needs.

Single Phase Electric Chain Hoist Solution

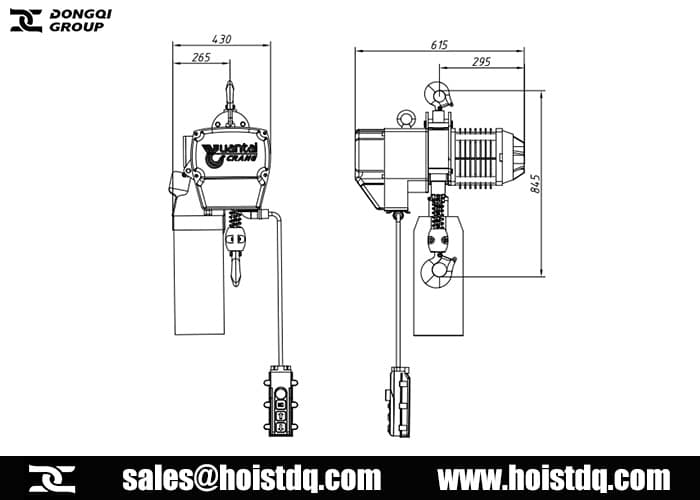

DQCRANES proposed a tailored solution in the form of a 3 ton fixed chain hoist with single phase, designed to meet the client’s requirements for lifting capacity and operational efficiency. The hoist was equipped with advanced features to ensure seamless integration into the client’s existing infrastructure, providing a comprehensive solution for their lifting needs.

- Durability: Manufactured with robust construction and high-quality materials for long-lasting performance in a workshop environment.

- Capacity: 3 tons (6,000 lbs) – sufficient for handling car engines, transmissions, and other heavy parts.

- Power: Single-phase electric (240V/60Hz) – compatible with the Dominican Republic’s electrical grid.

- Lifting Height: 16 meters available to meet the specific shop ceiling height.

- Lifting Speed: 5.6m/min lifting speeds for precise control during operation.

- Control: Push-button pendant control for easy operation.

- Overload protection to prevent lifting loads exceeding the hoist’s capacity.

- Upper/lower limit switches to stop the hoist automatically at the end of travel.

- Emergency stop button for immediate shutdown in case of emergencies.

Benefits

The 3 ton single phase electric chain hoist from DQCRANES found versatile applications within the client’s automotive repair shop. During repair and maintenance procedures, it was utilized for lifting engines, transmissions, chassis components, and other heavy vehicle parts. The hoist’s flexibility and ease of operation enhanced the efficiency of the shop’s workflow, allowing for seamless handling of heavy loads with precision and control.

Production and Delivery

Upon finalizing the specifications and design details, DQCRANES commenced the production of the customized single phase 3t electric chain hoist. The manufacturing process adhered to stringent quality standards, ensuring that the hoist met industry regulations and performance benchmarks. Once completed, the hoist was meticulously tested to validate its functionality and safety features before being prepared for delivery.

The delivery process was coordinated to align with the client’s schedule, ensuring minimal disruption to their operations. DQCRANES provided comprehensive support during the installation and commissioning of the electric chain hoist, ensuring seamless integration into the client’s facility. The dedicated technical team offered training sessions to familiarize the client’s staff with the operation and maintenance procedures, empowering them to utilize the hoist effectively.

Client’s Feedback

Following the successful installation and deployment of the single phase chain hoist, the client expressed their satisfaction with the solution provided by DQCRANES. They noted significant improvements in their lifting operations, citing the hoist’s reliability, precision, and ease of use as key factors contributing to enhanced productivity within their automotive repair shop. The client commended DQCRANES for their professionalism, attention to detail, and commitment to delivering a tailored solution that exceeded their expectations.

Electric Chain Hoist Applications

- Construction Sites: Lifting and maneuvering building materials, machinery, and tools.

- Warehouses and Distribution Centers: Loading and unloading pallets, crates, and other heavy objects.

- Manufacturing Facilities: Installing and positioning machinery, assembling equipment, and handling heavy parts on production lines.

- Automotive Repair Shops: Lifting engines, transmissions, and other car components.

- HVAC/R Applications: Installing and servicing heating, ventilation, and air conditioning equipment.

Free Quote

Here are main factors to consider when selecting a suitable electric chain hoist for your needs:

- Lifting Capacity: This is the most crucial factor. The electric chain hoist you select must have a capacity that is greater than the heaviest load you intend to lift. It is recommended to choose a hoist with a capacity that is at least 25% more than the heaviest load you expect to lift. This provides a safety buffer and reduces strain on the hoist.

- Lifting Height: This is the vertical distance the hoist can lift a load. Determine the height from where you will be suspending the hoist to the highest point where you will need to lift the load. Consider adding a buffer of a few feet to account for future needs or unforeseen circumstances.

- Lifting Speed: Electric chain hoists come in various lifting speeds. Choose a speed that is appropriate for your application. A slower speed might be sufficient for precise lifting operations, while a faster speed might be preferable for tasks that require quicker lifting and lowering of loads. DQCRANES also supplies dual lifting speeds for your needs.

- Duty Cycle: The duty cycle refers to the percentage of time the hoist will be in use over a given period. Hoists are classified into different duty classes, such as light duty, medium duty, and heavy duty. Select a hoist with a duty cycle that matches your application’s requirements.

- Power Supply: Electric chain hoists are available in various voltages and phases. Ensure that the hoist you choose is compatible with your facility’s power supply.

- Safety Features: Consider the safety features offered by the hoist, such as overload protection, upper and lower limit switches, and emergency stop buttons. These features are essential for safe operation and can help prevent accidents.

Contact us to get a free quote!