Background:

In the automotive industry, efficiency and precision are crucial in the assembly process. To meet the demands of this industry, high-quality equipment such as monorail hoists play a vital role in ensuring smooth operations. European standard 5 ton monorail hoists are designed to meet the rigorous requirements of automobile assembly workshops, providing reliable lifting solutions for heavy components and vehicles. As an established supplier of industrial equipment, we understand the specific needs of our clients in the American automobile assembly sector and are committed to providing top-notch hoisting solutions that enhance productivity and safety.

Client’s Requirements:

Our client, an American automobile assembly workshop, sought a robust and reliable lifting solution to streamline their production processes. They required a 5 ton monorail hoist that adheres to European standards for quality, safety, and performance. The client emphasized the importance of precision lifting, durability, and compatibility with their existing infrastructure. Additionally, they sought a supplier who could offer comprehensive support and expertise in integrating the hoist system into their assembly workshop.

European Standard Monorail Hoist Design Solutions:

In response to the client’s requirements, our team of experts devised a tailored solution centered around European standard 5 ton electric monorail hoists. We focused on integrating cutting-edge technology, safety features, and ergonomic design to deliver a hoisting system that aligns with the client’s needs. Our design solutions emphasize seamless integration, ease of maintenance, and adherence to stringent quality standards.

Technical Parameters:

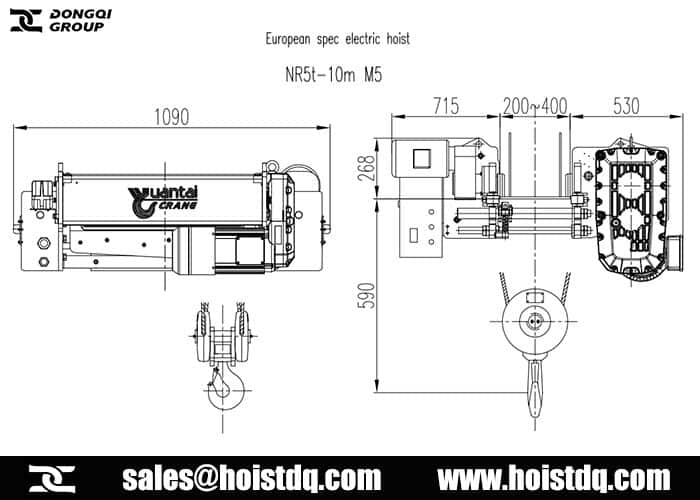

- Lifting capacity: 5t

- Lifting height: 10.1m

- Main lifting speed: 0.96/6 m/min

- Trolley traveling speed: 2.0~20 m/min STEPLESS

- Lifting power: 1.0/6.1 kW

- Trolley motor power: 0.64 kW

- Power supply: 220V/3Phase/60Hz

- Lifting group: FEM 2m (M5)

- Trolley traveling group: FEM 2m (M5)

- Control method: Pendent control

- Working site: Indoors

Design Details:

- Load Capacity: The monorail hoist system is engineered to handle a maximum load capacity of 5 tons, making it suitable for lifting heavy materials with ease and precision.

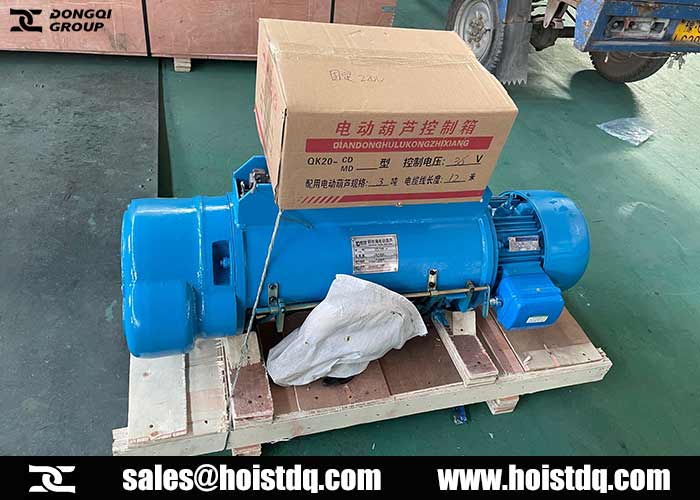

- Compact Structure: The 5 ton electric hoist is designed with a compact structure, allowing for seamless installation in various industrial settings where space may be limited.

- Precision Control: It incorporates advanced control mechanisms that enable precise positioning and movement of the load, enhancing operational efficiency and safety.

- Durability: The hoist is built to withstand rigorous industrial environments, featuring durable components that ensure long-term reliability and performance.

- Compliance with European Standards: As the name suggests, this monorail trolley hoist complies with European standards for quality, safety, and performance, ensuring that it meets the strict requirements set forth by regulatory bodies.

Design Features:

The European standard 5-ton monorail hoist is equipped with a range of features that contribute to its exceptional functionality and usability. Some notable features include:

- Hoisting Mechanism: The hoist utilizes a powerful hoisting mechanism that enables smooth and efficient vertical lifting of heavy loads, enhancing productivity in material handling operations.

- Safety Systems: It is equipped with comprehensive safety systems such as overload protection, emergency stop functions, and limit switches to prevent accidents and ensure operator safety.

- Variable Speed Control: The hoist offers variable speed control capabilities, allowing operators to adjust lifting speeds based on the specific requirements of the application, thereby optimizing performance and precision.

- High-Quality Components: From high-strength steel cables to reliable braking systems, the hoist incorporates high-quality components that contribute to its overall durability and performance.

- Remote Control Options: Some models are designed to support remote control operation, enabling operators to manage lifting tasks from a safe distance, further enhancing safety and convenience.

- Customization Options: Businesses can benefit from customization options that cater to specific operational needs, such as specialized hooks, extended lifting heights, or unique control interfaces.

Why Choose FEM Standard Monorail Hoist?

- Enhanced Productivity: With its high load capacity and precise control features, the hoist contributes to enhanced productivity in material handling tasks, reducing operational downtime and improving workflow efficiency.

- Safety Compliance: The hoist’s adherence to rigorous safety standards ensures compliance with industry regulations and promotes a safe working environment for operators and personnel involved in lifting operations.

- Versatility: Its ability to handle a wide range of materials and loads makes it a versatile solution for diverse industrial applications, from heavy machinery assembly to warehouse logistics.

- Long-Term Reliability: The durable construction and quality components of the hoist contribute to its long-term reliability, minimizing maintenance requirements and operational disruptions.

- Cost-Effective Operation: By streamlining lifting processes and minimizing the risk of accidents or material damage, the hoist offers a cost-effective solution for businesses seeking efficient material handling solutions.

Monorail Hoists for Automobile Assembly Workshop:

Our range of monorail wire rope hoists caters specifically to the needs of automobile assembly workshops, offering solutions for lifting vehicle components, engines, chassis, and other heavy loads with ease. The hoists are designed to optimize workflow efficiency, minimize downtime, and enhance overall productivity within the assembly facility. With a focus on precision engineering and user-friendly operation, our monorail hoists are tailored to meet the unique demands of automotive manufacturing processes.

Types of Monorail Hoists for Sale to America:

We offer a diverse selection of monorail hoists tailored for the American market, including single-girder and double-girder configurations to accommodate varying facility layouts and load requirements. Our hoists are available in both electric chain and wire rope variants, allowing clients to choose the most suitable option based on their specific lifting needs. Additionally, we provide customization options to tailor the hoist system to the unique requirements of each automobile assembly workshop, ensuring seamless integration and optimal performance.

Contact us today to explore our range of monorail hoists and discover how our lifting solutions can enhance your automobile assembly workshop’s operations.