Indoor overhead crane for EPS Sandwich Panel Factory in Paraguay

Indoor crane project is for the material handing in EPS sandwich panel factory in Paraguay. Indoor overhead crane project in project involves 10 ton single girder indoor overhead crane for steel panel handling. Now let’s read on the 10 ton indoor crane project in Paraguay EPS sandwich panel factory now.

Customer’s company profile

The Paraguay client is a manufacturer of thermal sandwich panels. They have several thermal sandwich panel production lines, which has certain influence in their local market.

Thermal sandwich panels from the Paraguay client Of DONGQI HOIST AND CRANE

Lifting requirements

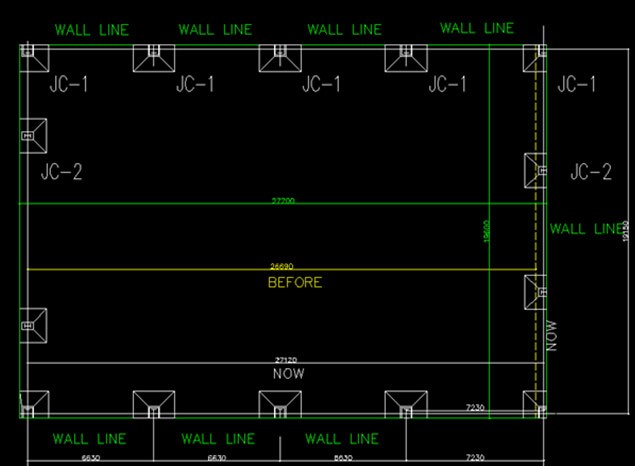

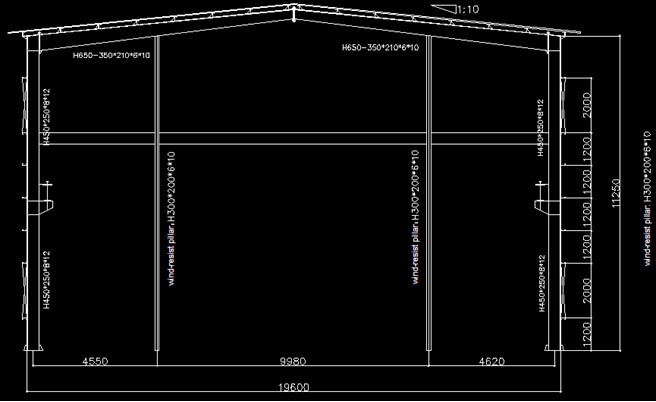

During the sandwich panel production, they need to move coils of steel sheet for stocking and for placing them in a continuous production line for EPS sandwich panel. Here comes the question: The factory has been built up within the wall with the height around 1.2 m which limits the working area of material handling. In order make the most of the working space, the client requires that the bucket should be set up closely against the wall. How to realize these requirements? See our solution diagram below:

Material handling solution

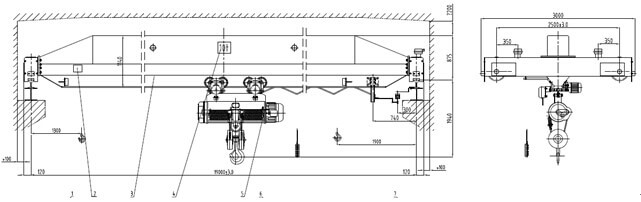

Based on the working conditions and lifting requirements, DONGQI HOIST AND CRANE recommended the Paraguay client the 10 ton single girder indoor crane, with a special designed bucket, at the corners the foundations of which are narrowed down to 1/4 of the normal size and special materials and additional bolts are used to ensure the stability and safety (Seen the designing drawing above).

The bucket and bolts for the single girder indoor crane

The single girder indoor crane can help the client to lift and move the coil of steel plates and the specially designed foundation can largely save space for the crane. At same time, the safety and stability of the indoor crane is guaranteed. The lifting requirements of the client are perfectly satisfied.

After the confirming of the crane drawing, everything went well with the crane production, packaging and delivery and installation.

Indoor crane shipment picture

DONGQI HOIST AND CRANE suggest customer choose the open top container due to irregular shape, since it’s easy for loading and unloading, and it is safe as well.

Customer’s installation site:

DONGQI HOIST AND CRANE provide detailed installation instruction, including mechanism and electric, it’s easy for customer if they choose to install it by themselves. We can also provide installation guide by phone or email or other communication tools if customer request.

Conclusion

As for the crane project, the features of the material handling solutions are:

1)10 ton single girder indoor crane can fully meet the material handling requirement of the coils of steel plates which is cost effective.

2) The special designed crane bucket and foundation can largely save the working space which on the other hand improves the cost-effectiveness of the single girder indoor crane.

3) The safety and stability of the crane is guaranteed with low cost.

DONGQI HOIST AND CRANE is always dedicated to provide optimal material handling solution for clients around world. No matter what kind of conditions you have and what kind of problem confronted, DONGQI HOIST AND CRANE will find the most ideal one for you. DONGQI HOIST AND CRANE is here to lift you up!

Indoor overhead crane cases of Dongqi Hoist and Crane

As the top overhead travelling crane and the biggest supplier in China, Dongqi Hoist and Crane has provided high-quality indoor overhead crane for many customers around the world, such as USA, Singapore, Africa, India, Egypt, Malaysia and so on.

Indoor crane: Capacity: 3.2~16t , Span: 7.5~28.5m, Height: 6~12m

Indoor crane: Capacity: 1-20t, Length: 7.5-28.5m, Height: 6-18m

Indoor crane: Capacity: 15t , Length: 10.5~31.5m , Height: 6~80m

Indoor crane: Capacity:5-320t, Length: 10.5~31.5m, Height: 6~18m

Indoor crane: Capacity :5-320t, Length: 10.5~31.5m, Height: 6~18m

Indoor crane: Capacity: 5~30t, Length: 10.5~31.5m, Height: 6~35m

Indoor cranes offering of Dongqi Hoist and Crane

Indoor crane for indoor material handling. Types of indoor cranes available, such as, indoor overhead crane, gantry crane, jib cranes, hoist crane, trolley crane, etc. Contact the Dongqi Hoist and Crane now to get more information on the cost-effective indoor overhead crane now.

Indoor overhead Crane

Single Girder electric hoist indoor Crane