The parts of a hoist defines the quality of the electric hoist. What is hoist parts development direction in China? Check the hoist parts development direction now.

wire rope electric hoist

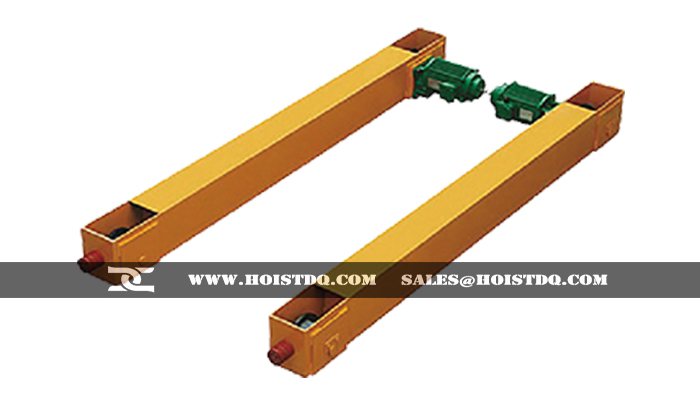

Wire rope electric hoist is a small sized lifting equipment, with compact structure, light weight, small volume, parts versatility, convenient operation, it can be installed separately on the I-beam, also can form a complete set of installation in the electric or manual single beam overhead crane, double girder overhead crane, jib crane, gantry crane, etc.

Hoist parts of wire rope electric hoist

To explore the wire rope electric hoist lifting accessories and hoist parts development direction in China.

- Appearance design changed the traditional circular design , using the square structure , modular design , increase the parts commonality, Arrangement model motor- intermediate shaft-reducer-drum, instead of motor-reducer-drum, can effectively improve the wire rope electric hoist lifting height , and avoid the long axis of the high speed shaft transmission , can improve the stability and reliability in operation and reduce the manufacturing cost.

- Improve the quality of hoist parts such as wire rope, bearings and other standard parts

- Structure should be able to meet a variety of conditions such as: low headroom, double lifting point and other installation fixed way ; Can be remote control type ,insulation , anticorrosive moisture proof , multiple functions such as resistance to high temperature high fever , explosion-proof products .

- Adopt high quality high strength steel wire rope, GB3811 1983 standard requirements, to meet tensile strength under the premise of safety factor, as far as possible reduce the diameter of wire rope, adopt appropriate to the drum diameter and diameter of wire rope and pulley diameter and the ratio of the diameter of wire rope, so narrowing the machine structure and self-respect

- Increase the electric protection measures, aside from the protection of the upper and lower limit, should add overload protection of underload protection (individual cases); Fault phase, lack of phase, the loss of pressure protection; Hook the rope off protection. Development more braking function models such as: double brake (motor conical wheel brake + high-speed shaft compensation brake); three brake (conical wheel brake braking + high-speed shaft compensation on safety brake drum). According to user’s need to increase the lifting height and load digital display function.

- Motor using 2, 4, 6, a conical rotor motor to apply all kinds of different working conditions. The motor insulation class levels should be raised to F and 11, protection grade up to IP54. Motor overheating protection device Settings; The design should consider prove the useful power of the motor, step down and up, braking ability; Improve the temperature rise of the motor design, give full play to the potential of the motor; Motor noise in addition to the design, processing, manufacturing precision to improve on the outside, also should consider design on electromagnetic noise reduction and air spiral noise measures. Motor design should also follow the principle of work level division, improve use single purpose.

- High wear resistance, high strength, guide line equipment and guide rope guideline performance has been the domestic many enterprises to explore production electric hoist, at present, domestic had mastered some successful experience.

- Improve the contactor, transformers and other electronic components of mechanical and electrical life of life, the appearance of electric cabinet design should be considered and the hoist plug body coordination.

- To optimize the design of the gear to improve the bearing capacity of the gear. Gear can use 40 CR or 42 CRMN , 40 MNB material , conditioning and surface hardening treatment or nitride , the original 20 CrMnTi or 20 MnTiB material while in bending strength and contact strength of gear is ideal , but influenced by domestic base level of processing , low gear machining precision , carburizing and quenching heat treatment deformation is difficult to control , after the sequence and no gear grinding process , unavoidably exist large gear noise , low efficiency of faults . In addition , the use of hard tooth surface and the matching of hard-toothed surface meshing gear pair , high-speed gear shaving process , gear helix Angle around 12~, these are the effective ways to improve gear transmission stability . Gear box, box cover structure design should be conducive to the absorption of noise and vibration reduction, transmission shaft promise to improve precision grade

The parts of a hoist defines the quality of the electric hoist. Dongqi Hoist and Crane is able to provide you types of hoist parts to renew the life of your electric hoist. Contact us for more information on Hoist parts now.