DQCRANES recently offered a single speed 2 ton polipasto de cable for a steel plant in Puerto Rico. The client, is a leading steel manufacturer in the region, specializing in the production of high-quality steel products for various industrial applications. With a focus on efficiency and safety, the client required a reliable and efficient lifting solution for their steel plate handling operations. After careful consideration of their requirements, DQCRANES offered a tailored wire rope hoist solution to meet their specific needs.

Recognizing the need for a specialized lifting solution, the client reached out to DQCRANES for their expertise in material handling equipment. DQCRANES has a proven track record of providing high-quality hoists and cranes for various industrial applications, making them the ideal partner for the client’s requirements.

Soluciones

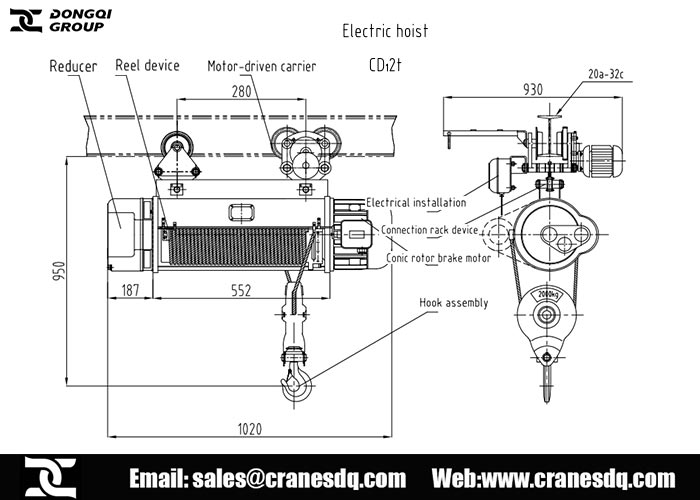

In response to the client’s needs, DQCRANES proposed a 2 ton single speed wire rope hoist as the ideal solution for their steel plant. The single speed design offered simplicity and reliability, making it well-suited for the client’s lifting operations. The 2 ton wire rope grúa para la venta was designed with a lifting height of 30 meters and compatibility with a three-phase power supply. The eléctrico polipasto de cable was engineered to deliver smooth and precise lifting of heavy steel plates, ensuring efficient material handling within the steel plant.

Los Detalles De Diseño

- Lifting Capacity: 2 tons

- Lifting Speed: 8m/min

- Lifting Height: 30 meters

- Viajando a la velocidad: 20m/min

- Working duty: M3

- Power Supply: 220V/60Hz/Three-phase (compatible with the client’s existing electrical system)

- Protection grade: IP54

- Insulation class: F

- Wire Rope: High-quality wire rope selected for strength and durability

- Motor: Powerful electric motor designed for efficient lifting operations

- Control System: User-friendly remote control for easy operation

- Hoist Body: Robust construction with a compact design for efficient use of space

Características De Diseño

- Durable Construction: Built with high-strength materials to withstand the demanding environment of a steel plant.

- Reliable Performance: Engineered for smooth operation and long service life.

- Características De Seguridad: Equipped with overload protection, limit switches, and emergency stop functions to ensure operator safety.

- Heavy-Duty Gearbox: Ensures smooth operation and long-lasting performance under heavy loads.

- Durable Brakes: Provide reliable stopping power and precise control.

- Dust-Proof Construction: Protects the internal components from dust and debris commonly found in steel plants.

Beneficios

- El Aumento De La Eficiencia: Faster lifting and lowering of steel plates improve overall production throughput.

- Aumento De La Seguridad: Safety features minimize the risk of accidents.

- Reducir El Tiempo De Inactividad: Durable construction ensures reliable operation and minimizes maintenance requirements.

- Improved Work Environment: User-friendly controls and smooth operation create a more comfortable working environment for operators.

La producción y Entrega

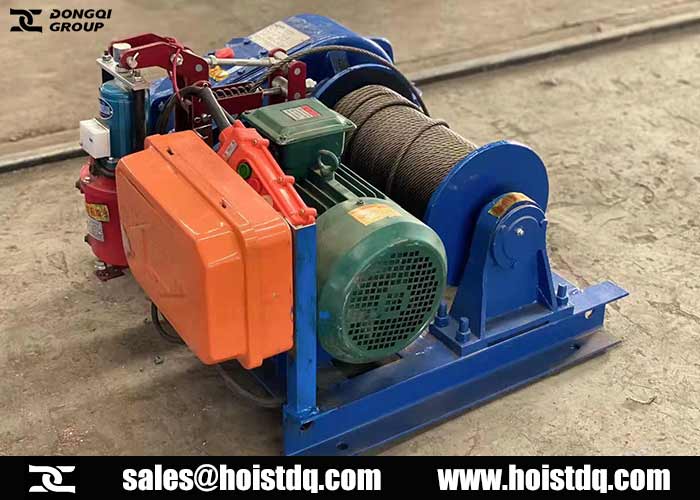

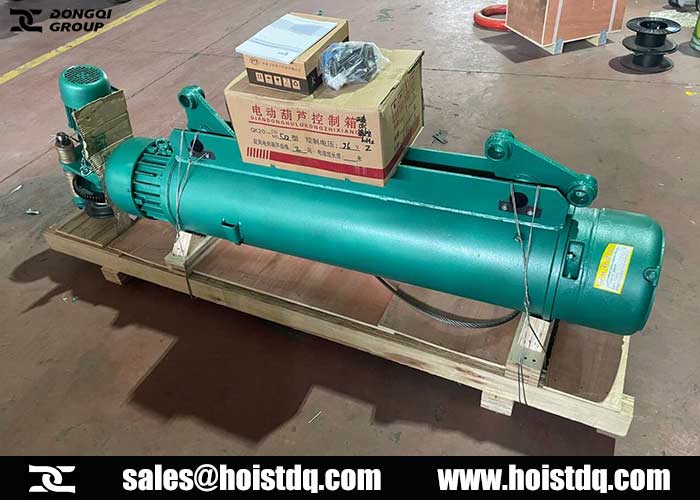

DQCRANES managed the production of the customized wire rope hoist according to the client’s specifications, ensuring strict quality control throughout the manufacturing process. Once completed, the 2 ton hoist and trolley were carefully packaged and delivered to the client’s steel plant in Puerto Rico, ready for installation and commissioning.

Instalación

DQCRANES wire rope hoists are easy to install and operate. Our professional technicians provided the client with comprehensive online installation guidance, and customers successfully installed the hoist and put it into use.

Wire Rope Hoist For Steel Plants

Wire rope hoists are essential equipment in steel plants for various material handling applications. DQCRANES offers several types of wire rope hoists designed specifically for the unique requirements of steel plants.

- Electric Wire Rope Hoists:

Electric wire rope hoists are powered by electricity and are widely used in steel plants for lifting and moving heavy loads. These hoists are known for their reliability, precision, and efficiency. They are available in various lifting capacities to suit the specific needs of steel plant operations.

In steel plants, where there is a potential risk of explosive atmospheres due to combustible materials, explosion-proof wire rope hoists are used to ensure safety. These hoists are designed to prevent the ignition of flammable gases or dust, making them suitable for hazardous environments in steel plants.

In steel plants with limited space, low-headroom wire rope hoists are an ideal choice for maximizing vertical lifting capacity within confined spaces. These hoists are designed to minimize the distance between the hook and the beam, allowing for efficient use of space in steel plant facilities.

- Trolley-Mounted Wire Rope Hoists:

For applications that require lateral movement of loads, trolley-mounted wire rope hoists are used in steel plants. These hoists are equipped with a trolley mechanism that allows for smooth and precise horizontal positioning of heavy loads, providing flexibility in material handling operations.

Steel plants often deal with extremely heavy loads that require robust material handling equipment. Heavy-duty wire rope hoists are specifically designed to handle the demanding lifting tasks in steel plants. These hoists are built with high-strength components and advanced features to ensure reliable performance under heavy loads.

- Custom Wire Rope Hoists:

Steel plants often require custom solutions to meet their unique material handling challenges. Custom wire rope hoists are designed and manufactured to meet specific requirements such as high-speed lifting, precise positioning, or extreme environmental conditions. These hoists are tailored to the exact needs of the steel plant, ensuring optimal performance and safety.

Each type of wire rope hoist offers unique features and benefits that cater to the specific requirements of steel plant applications. By choosing the right type of wire rope hoist, steel plants can ensure efficient and safe material handling operations, ultimately contributing to increased productivity and operational excellence. Contacto DQCRANES el día de hoy!