Metallurgical Electric proveedor de la grúa in China – DQCRANES

Metallurgical Electric Hoist is lifting equipment used in metallurgy environment for lifting and handling molten metal, it is improved product on the basis of CD, MD eléctrico de la grúa, with dual brake, double spacing, insulation boards and other varieties of protections, working level is M6. It is safe, reliable, parts with high degree of universality and compact structure.

Metallurgy heat resistance electric hoist model YH is an ideal light-duty lifting device, which can be used together with metallurgical single girder grúa de arriba and can be installed under the fixed lifting monorail or beam in the workshop for separate use.

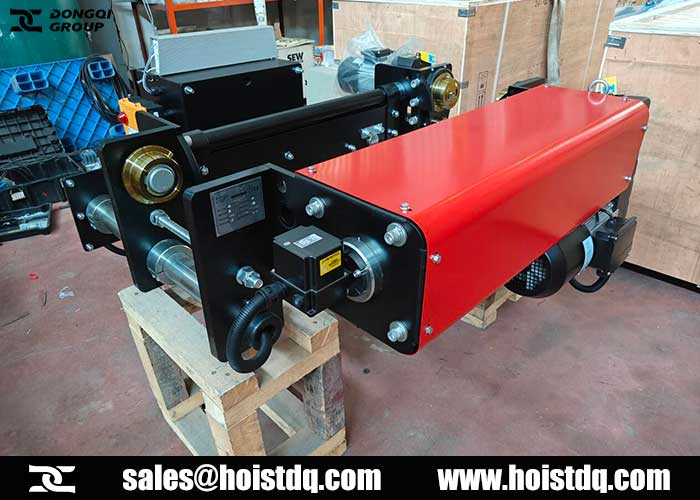

Metallurgical Electric Hoist To Mexico

This eléctrico polipasto de cable is Metallurgical la grúa monorraíl designed for a metallurgy plant in Mexico.

- Product: Monorail Hoist

- Capacity: 7 Tons

- Lift Height: 6 Meters

- Model: YH

- Lifting Speed: 7 m/min

- Traveling Speed: 20 m/min

- Application: Used for lifting molten metal.

- Export Country: Mexico

DQCRANES Metallurgical Electric Hoist is a heat resistance polipasto de cable designed for the metallurgy industry. It can be used for lifting molten metal. The working temperature reaches 60 degrees Celsius. Its lifting capacity is no more than 20 tons and lifting height is no more than 100 meters.

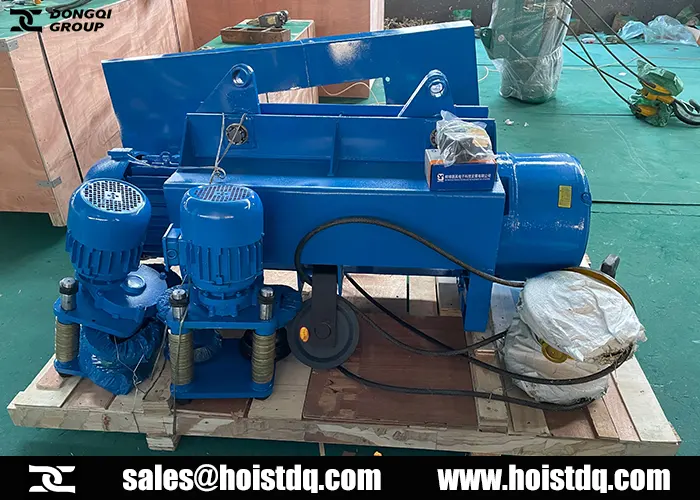

Metallurgical Electric Hoist Design Features

Metallurgical Electric cable hoist mainly consists of lifting mechanism, traveling mechanism, electrical control system, and the second braking device. With dual brake, double spacing, insulation boards and other varieties of protections. Using YZD series conical rotor motor, protection class IP54, motor insulation class H, the motor comes with cone brake, hoisting mechanism with other safety brake as its own.

Double spacing protection

- Metallurgical Electric Hoist lifting mechanism is double limit protection, the first stage protection is off the fire limit protection, and the second stage protection is off control limit protection. When the hook up to the safety limit position, the first stage off the fire limit protection starts. When the first stage limit protection failure, the second stage limit immediately de-energize the total contacts to play a role on protection.

Dual brake protection

- Metallurgical Electric Rope Hoist operating in dangerous environment, with double brakes. During normal operation, the second brake does not work, and only when lifting heavy object, the first brake failure or shaft and gear broken, the object falls freely, drum speed reaches a certain speed (1.25 times than normal speed), then the second brake braking the object in the air in order to achieve safe braking.

High temperature protection

- Metallurgical Electric Hoist set the insulation protection in the below, effectively avoid direct heat radiation. In order to prevent the wire rope or cable from damage under high temperature during operation, there use high temperature resistance steel core wire rope and cable.

Operation Mode

- In order to ensure the safety of operating personnel and equipment, Metallurgical Electric Hoist set up with remote control and ground control operation together use control mode. Mainly use remote control. Ground control operation only used temporarily when remote control operation fails.

Safety devices

- In addition to double limit protection, dual brake protection and high temperature protection, as well as short-circuit protection, no-voltage protection, electrical interlock protection, overspeed protection and other multiple security protection devices.

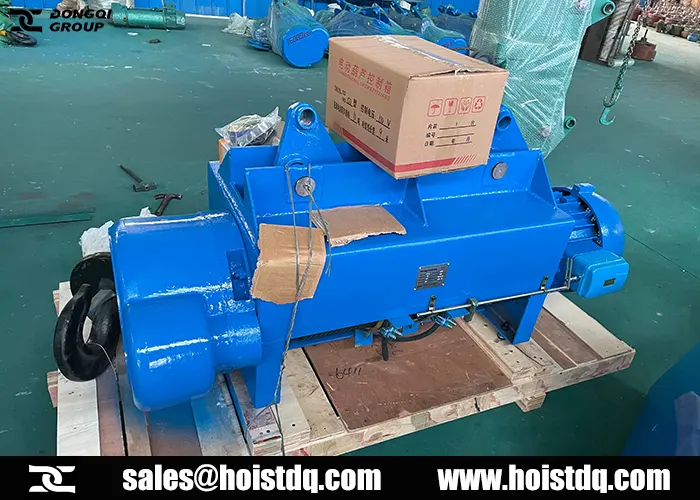

Application Scope of Metallurgical Electric Hoist

- The metallurgical electric hoist is installed on the I-steel track to lift heavy objects, and can reciprocate in a straight line and a curve along the track to ensure sufficient safety. It is suitable for working in an environment without fire, explosion hazard and corrosive medium. It is suitable for lifting molten metal and working in dangerous places. Double brakes are not allowed to disassemble and use one brake.

- cuerda de alambre eléctrico de la grúa for metallurgy is an electric hoist specially designed for metallurgy and molten metal industry on the basis of CD1 and MD1 electric hoists in accordance with relevant national regulations and requirements. The working level of metallurgical electric hoist is M5, M6, and the working environment temperature is not higher than 60°C. , The altitude is below 100M.

- This series of products can lift molten metal, but in low temperature below 10C or high temperature above 50*C, in places with explosion hazard, full of sulfuric acid and corrosive gas, and in places where toxic and flammable materials are lifted Prohibited to use to ensure safety and reliability.

- The steel wire rope electric hoist for metallurgy has added a safety brake directly set on the drum, which achieves the maximum safety of lifting products. It is recommended to use remote control for this product.

Get your custom eléctrico de la grúas

- Load capacity_ton?

- Lifting height_m?

- Industry:

- Application/Working: what materials to be lifted?

- Voltage preferred: 380V, 3Phase, 50Hz or other request?

- Quantity:

- Operation: Through Pendant/Radio Remote?

If you do not know about how to select the electric hoist, please feel free to leave us a message or email to sales@hoistdq.com. The reply of our electric hoist engineer will be given within 24 hours. Get your custom design electric hoist.