eléctrico de la grúa Case in Thailand

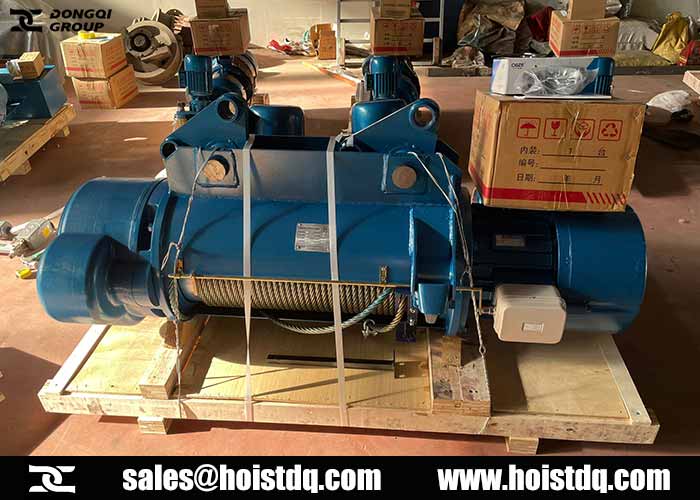

- Product: MD1 Double Speed polipasto de cable

- Lifting capacity: 16 tons

- Lifting height: 9m

- Lifting speed: 0.35/3.5m/min

- Traveling speed: 2~20m/min

- Working duty: M3

- Power supply: 380V/50Hz/3 Phase

- Application: Manufacturing industry, Indoor

DQCRANES, a leading material handling equipment manufacturer, recently provided a 16 ton double speed wire rope hoist to a manufacturing firm in Thailand. The manufacturing firm, which specializes in heavy-duty industrial equipment, required a reliable and efficient hoisting solution to enhance their production processes.

The MD model double speed wire rope hoist offered by DQCRANES is designed to meet the specific needs of the manufacturing firm. With a lifting capacity of 16 tons, the hoist can easily handle heavy loads, making it an ideal choice for the firm’s operations. The double speed feature allows for precise control during lifting and lowering, ensuring safety and efficiency in the handling of materials.

The double speed hoist is built to the highest standards, utilizing high-quality materials and advanced engineering to ensure durability and long-term performance. This was particularly important for the manufacturing firm, as they required a hoisting solution that could withstand the rigors of their demanding industrial environment.

Furthermore, DQCRANES provided comprehensive support throughout the entire process, from initial consultation to installation and commissioning. Our team of experienced engineers worked closely with the manufacturing firm to understand their specific requirements and ensure that the hoist was seamlessly integrated into their existing infrastructure. This level of personalized service and attention to detail further solidified the Thailand manufacturing firm’s confidence in choosing DQCRANES as their hoisting solution provider.

The successful implementation of the 16 ton electric hoist has had a significant impact on the Thailand manufacturing firm’s operations. The enhanced lifting capabilities have improved efficiency and productivity, allowing for smoother handling of heavy components and equipment. This has resulted in streamlined workflows and reduced downtime, ultimately contributing to cost savings and increased output for the firm.

Why Wire Rope Hoist for Manufacturing Industry?

- Superior Strength and Durability:

Wire rope hoists are designed to withstand the rigorous demands of the manufacturing environment. The use of high-quality steel wire ropes ensures superior strength and durability, allowing them to lift and transport heavy loads with ease. This durability translates to long-term cost savings for manufacturing facilities, as wire rope hoists require minimal maintenance and have a longer service life compared to other lifting solutions.

- Versatilidad:

Wire rope electric hoists are available in a wide range of configurations, including single and double girder designs, as well as various lifting capacities to accommodate the diverse needs of the manufacturing industry. This versatility allows for seamless integration into different manufacturing processes, whether it’s for assembly line operations, material handling, or warehousing applications.

- Precise and Efficient Operation:

Manufacturing operations often require precise and efficient lifting and positioning of heavy components or materials. Wire rope hoists are equipped with advanced control systems that enable operators to perform intricate lifting tasks with precision. This level of control not only enhances safety but also improves overall operational efficiency in the manufacturing facility.

- Space-Saving Design:

In today’s manufacturing facilities, space optimization is crucial for maximizing productivity. Wire rope hoists are designed to minimize the footprint required for lifting operations, making them an ideal choice for facilities with limited space. Their compact design allows for efficient use of overhead space, freeing up valuable floor space for other essential operations.

- Características De Seguridad:

Safety is paramount in the manufacturing industry, and wire rope hoists are equipped with various safety features to ensure secure lifting operations. From overload protection systems to emergency braking mechanisms, wire rope hoists are designed to mitigate potential risks and provide a safe working environment for operators and other personnel in the facility.

- Customization Options:

Manufacturing processes vary widely across different industries, and wire rope hoists offer customization options to meet specific application requirements. Whether it’s special lifting attachments, speed variations, or specific control interfaces, wire rope hoists can be tailored to suit the unique needs of a manufacturing facility.

How to Choose Wire Rope Hoist?

Here are some key considerations to help you choose a suitable wire rope hoist for your needs:

- Capacity: You need to determine the maximum weight that the hoist will need to lift regularly, as well as any potential future requirements.

- Lift height: The lift height refers to the distance the hoist will need to raise and lower the load.

- Duty cycle: Consider the frequency and duration of hoist usage when determining the duty cycle requirements.

- Lifting speed: The speed at which the wire rope hoist can lift and lower the load is an important factor to consider, especially in applications where efficiency and productivity are critical.

- Medio ambiente: Factors such as temperature, humidity, dust, and corrosive substances can all impact the performance and longevity of the equipment.

- Safety features: Look for hoists that are equipped with essential safety features such as overload protection, emergency stop buttons, limit switches, and redundant braking systems.

- Power source: Hoists are available in electric and manual configurations, each with its advantages and limitations. Choose a power source that aligns with your operational requirements and infrastructure.

- Customization options: Depending on your specific needs, you may require certain customization options for your wire rope hoist, such as special controls, trolleys, or specific hook configurations.

For expert guidance on choosing the right wire rope hoist for your needs, contacto DQCRANES now to discuss your application and explore the best hoist solutions available.