Client Background

The UAE-based client, a forward-thinking steel bar producer, aimed to establish a state-of-the-art facility to meet the growing regional demand for construction materials. The factory required robust overhead cranes to handle raw steel coils, finished bars, and machinery across production zones. Key requirements included:

- Compliance with European safety and performance standards.

- Resilience to the UAE’s extreme heat (up to 50°C) and dusty conditions.

- Flexibility to manage loads of 5 tons (for precision tasks) and 8 tons (for heavy lifting).

- Rapid deployment to align with the factory’s construction timeline.

Challenges

- Harsh Environmental Conditions: High temperatures and airborne particulates risked affecting crane electronics and mechanical components.

- Regulatory Compliance: Meeting European standards and UAE’s import regulations for industrial equipment.

- Logistical Complexity: Shipping crane kits cost-effectively while ensuring timely on-site assembly.

- Operational Precision: Handling long, irregularly shaped steel bars demanded specialized lifting attachments.

Custom Crane Kits Solutions – DQCRANES

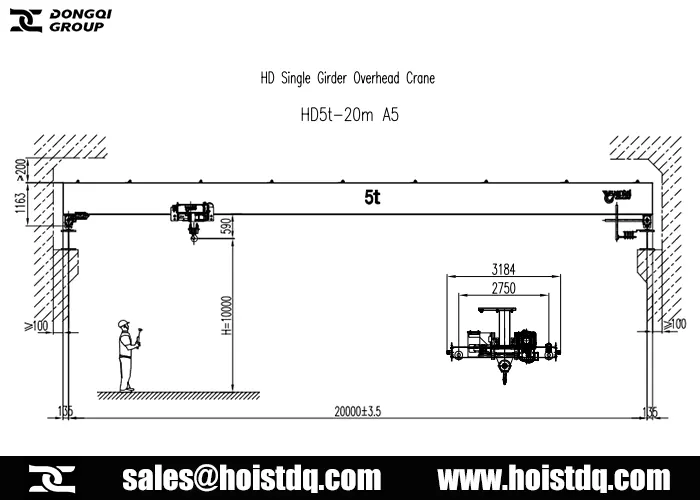

5 Ton grúa de arriba Kit:

The 5 ton crane kit was designed for lighter material handling tasks within the facility. Equipped with advanced hoisting mechanisms and precision controls, this 5 ton overhead crane ensures smooth and efficient operations while maintaining safety standards.

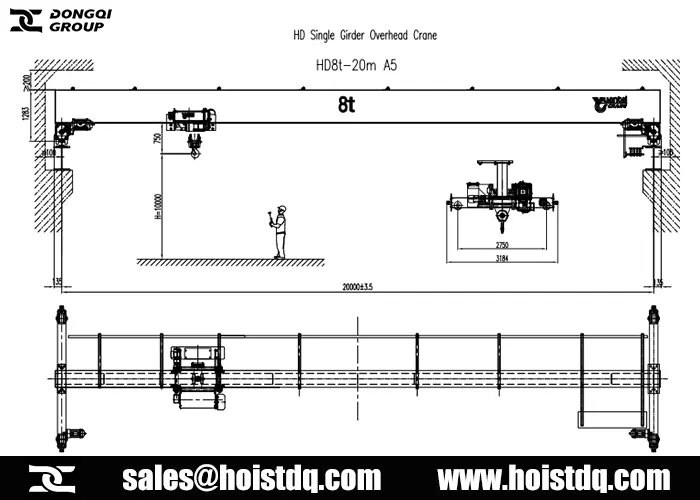

8 Ton Overhead Crane Kit:

The 8 ton crane kit was engineered for more demanding lifting operations, such as handling larger bundles of steel bars or heavier materials. Its robust construction and enhanced lifting capacity make it ideal for high-intensity tasks.

Both crane kits were designed with European standards, ensuring superior performance, safety, and reliability. Key components such as hoists, end carriages, and electrical systems were meticulously selected to meet the client’s operational needs while adhering to international quality benchmarks.

Specifications

| Producto | HD series overhead crane kits | HD series overhead crane kits |

| Capacidad de elevación | 5 ton | 8 ton |

| Span | 20m | 20m |

| Height of lift | 10m | 10m |

| Hoisting Speed | 0.8~5.0 m/min Stepless | 0.8~5.0 m/min Stepless |

| Traversing Speed | 2.0~20 m/min Stepless | 2.0~20 m/min Stepless |

| Traveling Speed | 2.0~20 m/min Stepless | 2.0~20 m/min Stepless |

| Weight of Trolley | 0.52 ton | 0.92 ton |

| Runway Rail Size | P15 | P22 |

| Crane Classification | FEM 2m (A5) | FEM 2m (A5) |

| Hoist Group | FEM 2m (M5) | FEM 2m (M5) |

| Control Voltage | 380V, 60Hz, 3Phase | 380V, 60Hz, 3Phase |

| Supply Power | 6.85kW | 10.06kW |

| Control Method | Pendent control & Remote control | Pendent control & Remote control |

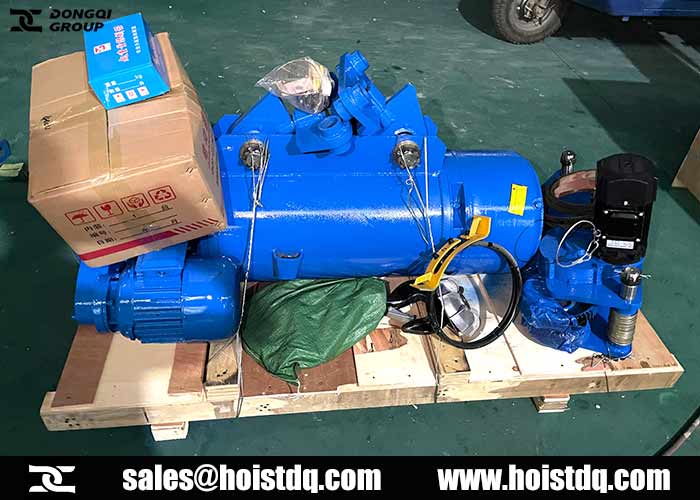

Includes

- NR series polipasto de cable with Motorized Trolley

- Motorized End Trucks with Wheel and Motor

- All Limit Switches, Buffers

- C-track Festoon Electrification System with Flat Cables

Not Included (unless otherwise stated in this offer)

- Structural Steel – Main Girder, Crane Service Platform

- Busbar System – Crane Runway Power Supply

- Runway rails

Export & Installation

Each crane kit was carefully packaged to prevent damage during transit, and detailed documentation was provided to facilitate smooth customs clearance. Upon arrival at the site, DQCRANES’ technical team collaborated with local engineers to oversee the installation process. Comprehensive training sessions were also conducted to familiarize the client’s staff with the operation and maintenance of the cranes.

Impact

Assembly Efficiency: Kits were assembled in 15 days, 20% faster than traditional methods.

Performance Testing: Dynamic load tests confirmed stability under 110% of rated capacity, exceeding UAE regulatory requirements.

Comentarios

“The successful implementation of the overhead crane kits has significantly enhanced the operational efficiency of the steel bars factory. We are very satisfied with DQCRANES’ professionalism, technical expertise, and commitment to delivering customized solutions.” — Factory Operations Manager

Why Choose Crane Kits Over Overhead Cranes?

- Cost-Effectiveness

One of the most significant benefits of crane kits is their affordability compared to purchasing a fully assembled overhead crane. With crane kits, you’re essentially buying the core components—such as the hoist, end trucks, and controls—without the additional cost of pre-assembly or installation. This allows businesses to allocate their budgets more efficiently, especially if they already have the expertise or resources to handle assembly in-house.

- Customization and Flexibility

Crane kits provide a high degree of flexibility, making them ideal for businesses with unique requirements. Unlike pre-assembled overhead cranes, which come in standardized configurations, crane kits allow you to customize the system to fit your specific workspace dimensions, load capacities, and operational needs. This level of adaptability ensures that your lifting solution is tailored to your operations, maximizing efficiency and productivity.

- Ease of Transportation

Shipping a fully assembled overhead crane can be logistically challenging and expensive due to its size and weight. Crane kits, on the other hand, are shipped as individual components, making transportation more straightforward and cost-effective. This can be particularly advantageous for businesses located in remote areas or those with limited access to large shipping facilities.

- Simplified Installation

The crane kits come with detailed instructions and support from manufacturers, enabling smooth installation. This approach also allows businesses to schedule assembly at their convenience, reducing downtime and disruptions to operations.

- Upgradability and Maintenance

Crane kits are often easier to upgrade or modify than complete overhead cranes. As your business grows or your lifting requirements change, you can replace or enhance individual components without needing to overhaul the entire system. Additionally, maintenance is simplified because you have direct control over the components, making it easier to source replacements and perform repairs.

- Ideal for Retrofitting

If you already have existing infrastructure in place—such as runways or support beams—a crane kit can be an excellent solution for retrofitting. Instead of investing in a full overhead crane system that may include redundant components, you can integrate a crane kit into your current setup, saving time and money.

Conclusión

DQCRANES crane kits are designed to deliver superior performance, safety, and durability. From cost savings and customization flexibility to simplified logistics and faster lead times, crane kits empower you to build an overhead crane system that perfectly aligns with your operational needs.

Contacto DQCRANES today, and you will get custom crane kits to maximize value for your business operations.