Getting started to buy chain block

Planning is the crucial factor in a successful chain block application. This process helps identify requirements and available resources. Obtain input from a variety of sources — engineers, maintenance staff, operators, distributors, and manufacturers — before making the selection.

Application should be clearly defined. Will the chain block be used solely to lift materials and equipment, or will it lift and move these items? The answer dictates the type of chain block needed.

Capacity is obviously important. How much weight will the chain block lift and/or move? Other factors include the height of the lift, height of the hook point (where the chain block will be mounted), and type of operator interfaces, such as hand chains or push-button pendants.

Frequency of use is critical. If lifting and moving loads frequently, an electric chain block is the best choice. If the chain block will only be used occasionally, a hand chain block should suffice.

If a trolley is required for horizontal motion, the type installed should correlate with the frequency of use. A plain or geared trolley requires the operator to start and stop the movement of the load by hand. Manual trolleys are usually satisfactory for occasional lifts and intermediate loads. A motorized trolley is ideal for frequent, heavy loads.

Electrical requirements

Determine available voltage and whether it is single or three phase. Industrial three-phase power is the preferred choice, because it is more efficient and there is more equipment from which to choose. Single-phase chain blocks should only be considered if three-phase power is not available.

If the application requires a trolley, give thought to getting power to the chain block. The most common approach is a festoon system consisting of a flexible power cord attached to rollers. Rigid conductors and collectors are another popular way to conduct power to the chain block.

Regardless of the electrical requirements, the chain blocking system needs a power disconnect and overcurrent protection. These and other requirements are specified by the National Fire Protection Association, National Electrical Code, and OSHA.

Measure headroom

Another important pre-installation factor is headroom, which is the minimum distance between the two hook points. Determine the height of the chain block’s bottom hook, as well as the height of the upper hook point. Make sure the chain block meets headroom requirements. Typically, lug-mounted chain blocks have less headroom (C) than hook-mounted models

Compare the distance between those heights with advertised headroom values from the chain block manufacturer. If required headroom is less than what is available as standard, change the hook point or obtain a chain block specially designed with a lower headroom.

Final planning

Work closely with an experienced electrical contractor, construction firm, and distributor to define requirements and select the proper components. Be sure that the building structure meets chain block system requirements.

Make sure all chain block operators read the operating and maintenance instructions provided by the manufacturer before using the equipment. Complete and return warranty certificates to the manufacturer. File the parts list and maintenance instructions for future reference.

Installation procedures

Allow ample time to complete the installation. Remember that the operator needs good solid footing and plenty of room to maneuver the chain block without interfering with normal traffic flow. Make sure the power source is turned off and properly locked out before beginning the installation.

Ensure the structure will support the chain block, as well as the hook or lug. If the chain block will be used with a trolley, install the trolley stops at each end of the beam. Then follow the manufacturer’s instructions for hanging the trolley, which should be properly adjusted to the beam size. Once the trolley is secured, hang the chain block to it.

Next, begin a series of checks and tests. For example, the top hook should be seated properly in the hook point, and the hook latch should be closed. Check all clearances for the chain block, trolley, and crane system (if necessary) to ensure there is unobstructed movement. Make sure all nuts, bolts, and pins are secured in the chain block/trolley system.

Electrical connections should be secured, circuit protection in place, chain block and building voltage matched, wires sized according to code, and line phase matched to the chain block.

If the chain block is manual, move the chains and trolley — with no load — to ensure they travel freely.

Activate the power to check for proper operation. With no load on the chain block, run it and the trolley through their full range of motion. Make sure the travel limit switches work properly. Test the chain blocking system with about 10% of rated capacity, and watch and listen for anything unusual. If the chain block passes this test, operate the unit with a full load.

If the chain block passes both tests, do one final check of the entire system. As a precaution, reread the manufacturer-supplied instructions and double check that all operators have the proper training and education to run the chain block.

Inspection and maintenance

Regular inspection and maintenance programs keep the chain block running efficiently and productively. They help ensure that the chain block is in proper working order for many years to come.

Inspections include checks for external damage, loose parts, worn chain, stretched hooks, and lack of lubrication. Be sure to examine chain blocks after storage and transportation. If a chain block doesn’t pass inspection, tag it “Out of Service” and remove it from the area for repair by a chain block specialist.

Maintenance extends chain block life. Establish a regular routine for qualified personnel to follow. Prescribed methods and appropriate materials are available in the chain block manufacturer’s operating and maintenance manual, or by checking with organizations such as OSHA, ASME, and ANSI.

Different kinds of chain blocks require various maintenance levels and procedures. For example, a manual chain block contains bearings, bearing points, gears, and other parts that require regular maintenance. An electric chain block requires maintenance on push button switches, contactors, and cables.

The proper kind and amount of lubrication help reduce friction and wear, and prevent parts from rusting. Likewise, worn or failing components should be replaced with new parts, according to the manufacturer’s specifications. Make sure replacement parts meet or exceed those specs. Also, protect the load chain from weld spatter or other damaging contaminants. Always keep maintenance records current.

Consult now to buy chain block for your application perfectly.

Hoisting equipment offering of Dongqi

Various tipos de polipastos are provided by Dongqi Group, the following list will give you a general introduction of Dongqi Hoists. Please contact us to select the right Hoists and lifting equipment for you application.

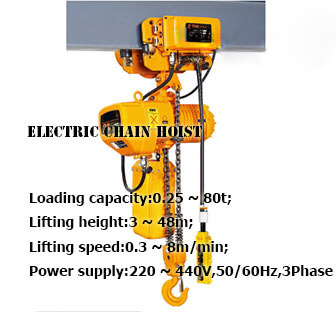

la cadena eléctrico de la grúa

| The electric chain hoists can be used to handle material with the lifting capacity of 0.5 ton to 35 ton, lifting height of 3 to50m, with the working class of M3 and M4. Hoistdq offers you various types of electric chain hoists to solve you material handling solutions. |

| DHS Series Electric Hoists, | TCH de la serie de la Cadena Eléctrico de la Grúa | DHP serie de Polipastos Eléctricos de Cadena |

|

|

|

| DHS Series Electric Hoists:1 ton, 2 ton, 3 ton, 5 ton,10 ton | TCH series Chain Electric Hoist:1 ton, 2 ton, 3 ton, 5 ton,10 ton | DHP series Chain Electric Hoists:1 ton, 2 ton, 3 ton, 5 ton,10 ton |

Más información acerca de La Cadena Eléctrico De La Grúa, please click.

Wire rope electric hoists

|

Electric hoists and electric hoists- wire rope single speedWire rope electric hoist single speed 0.25 ton, 0.5 ton, 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, 16 ton |

Please click for more information about Wire Rope Electric Hoist.

Doble velocidad de polipastos eléctricos

|

Dongqi Hoists can provide you double speed electric hoists with the lifting capacity of 0.25 ton to 32 ton. cuerda de alambre eléctrico de la grúa double speed 0.25 ton, 0.5 ton, 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, 16 ton |

Please click for more information about El Doble De Velocidad Eléctrico De La Grúa.

Europea polipastos eléctricos

|

Europea eléctrico de la grúa is a newly developed material handling equipment with advanced design technology according to the FEM standards, European hoist standards and other regulations. The lifting capacity of the European electric hoist is 1 to 80 tons and the working class is M5 and M6. |

Please click for more information about Europea Eléctrico De La Grúa.

|

Dongqi Hoists can provide explosion proof hoists with the lifting capacity of 0.25 ton to 63 ton, and the lifting height of 1 m to 100m, with the working class of M3. What’s more, single speed explosion –proof hoists and double speed explosion-proof hoists. And, customized explosion proof hoists are available. |

Please click for more information about A Prueba De Explosión Eléctrica De La Grúa.

Metalúrgico, eléctrico de la grúa

|

Metalúrgica de la grúa ofrecidos por Dongqi tiene una capacidad de elevación de 1-10ton, altura de elevación 9-30, la clase obrera de M6. Y personalizado metalurgia polipastos de industrias metalúrgicas están disponibles. |

Please click for more information about Metalurgia Eléctrico De La Grúa.

|

Mini electric hoist single hook 100 kg , 125 kg, 150 kg, 200 kg, 250 kg, 300 kg, 400 kg, 500 kgMini electric hoist with double hook 200 kg, 250 kg, 300 kg , 400 kg, 500 kg electric hoist

The lifting speed of the mini or small hoists can be up to 10 m/min. |

Please click for more information about Mini Polipasto Eléctrico?.

Manual hoist and hand hoist

Manual hoist and hand hoist is a type of light hand operated hoisting equipment, which solves the material handling problems with man power, with the features of easy operation, cost-effective, wide application, etc. Dongqi Hoist offers types of manual hoists or hand operated hoists, such as, manual

Manual hoist – Chain type

| CB-1 manual hoist | CB-11 manual hoist, | VC-B manual hoist |

|

|

|

| CB-1 manual hoist series:1 ton, 1.5 ton , 2 ton , 3 ton , 5 ton, 10 ton

|

CB11 series manual hoists: 1 ton, 1.5 ton , 2 ton , 3 ton , 5 ton, 10 ton | VC-B manual hoist:0.5 ton 1 ton ,1.5 ton, 2 ton, 3 ton, 5 ton, 10 ton, 20 ton, 30 ton, 50 ton , |

| CK type manual hoist | SK Series of manual hoist | HS-T type manual hoist |

|

|

|

| CK type manual hoist 1 ton, 1.5 ton , 2 ton , 3 ton , 5 ton , 10 ton , 20 ton, | SK Series of manual hoist 0.5 ton, 1 ton , 1.5 ton , 2 ton, 3 ton , 5 ton , 8 ton , 10 ton, 16 ton , 20 ton | HS-T series of manual hoist 0.5 ton, 1 ton , 1.5 ton , 2 ton, 3 ton , 5 ton , 8 ton , 10 ton, 16 ton , 20 ton, |

| HS-C type series manual hoist | HS-Z type series manual hoist |

|

|

| HS C Series of manual hoist 0.5 ton, 1 ton , 1.5 ton , 2 ton, 3 ton , 5 ton , 20 ton, | HS-Z series Series of manual hoist0.25 ton,? 0.5 ton, 1 ton , 1.5 ton , 2 ton, 3 ton , 5 ton ,10 ton , 15 ton, 20 ton ,30 ton, |

Please click for more information about manual chain hoists.

| Manual hoist- explosion-proof type | |

|

|

| Explosion proof hand hoist 0.5 ton, 1 ton,2 ton, 3 ton , 5 ton , 10 ton, 20 ton | VN explosion-proof manual hoist t 0.5 ton, 1 ton , 1.5 ton , 2 ton, 3 ton , 5 ton , 10 ton, 20 ton, etc |

Please click for more information about manual chain hoists.

Manual hoist and hand hoist – Lever type

| VC-A series lever hoist | VA series hand hoist | VD type lever hoist? |

|

|

|

| VC-A series manual hoist 0.5 ton, 1 ton, 1.5 ton, 2 ton , 3 ton , 5 ton , 10 ton , 20 ton , 30 ton, 50 ton , | VL lever chain hoist 0.5 ton ,0.75 ton ,1 ton , 1.5 ton, 2 ton , 3 ton, 6 ton, | VD type lever 250 kg, 500 kg , 750 kg, 1500 kg , 2500 kg ,3000 kg, 5000 kg, 60000 kg , |

Wire rope lever hand hoist

Wire rope lever hand hoist 0.8 ton, 1 t ton, 1.6 ton, 3.2 ton, 5.4 ton, etc.

Please click for more information about ?leaver hand hoists.