What is the different of dual hoist brakes system with both mechanical load brakes and motor brakes and single hoist brake system with motor brake only? How to select the braking system for your eléctrico de la grúa?

Hoist brake introduction

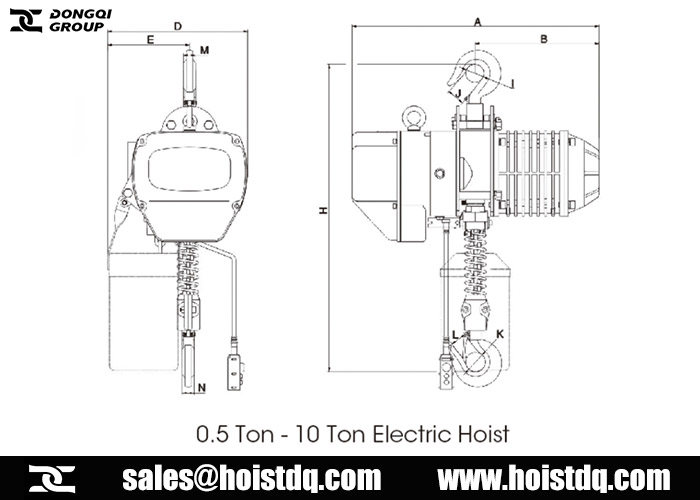

Electric hoists according to different standards and material handling requirements, the hoist brakes systems may vary.

To start with, electric hoists are mainly built with a motor brake. These hoist brakes by design are magnetically spring loaded and referred to as “fail safe.” In the case of the loss of power or when the electric hoist operator releases either the up or down push button, the electromagnets will release the brake and the springs set the brake. The brake manufacturer sizes the brake according to torque and the electric hoist manufacturer chooses the correct brake per the hoist motor horsepower. Some electric hoist manufacturers produce their own motor brakes for the electric hoist and some buy a motor brake from an outside source.

Mechanical load brake

A mechanical load hoist brake, also known as Weston type mechanical load brake, is by definition a mechanically operated brake, located in an oil bath.

The function of the mechanical hoist brake is to act as a secondary brake, in case of motor brake failure. While the electric hoist load is lowered, it also assists the electric hoist motor in controlling the load against the force of gravity, which is realized by absorbing energy and dissipating this energy in the form of heat, in the oil bath. This is why an electric hoist gear case will feel hot during operation. Some electric hoist manufacturers offer the mechanical load hoist brake as standard equipment and for other fabricante de la grúa, it is optional.

Dual hoist brake system

For most hoist applications, a single hoist brake meets all safety needs. However, some end users insist on “dual redundant holding brakes”, which can be accomplished by using

- 1) An electric hoist with a motor brake and a mechanical load brake, or

- 2) An electric hoist with dual motor brakes.

Both tipos de grúa brake system ensure maximum safety by providing a secondary hoist braking system provided that the primary brake fail. This is an important hoist safety consideration for applications with critical lifts over processes or operations where a motor brake failure would have catastrophic consequences.