Monorail lifting system

Monorail lifting system for various material handling. Dongqi monorail lifting system, la grúa monorraíl system, overhead monorail system for your selection. Check Dongqi monorail lifting system now.

What is a monorail system? Monorail lifting systems are standard, “out of the box” assemblies. But overhead hoists can also be configured for custom applications. When deciding what hoist is best for a certain lifting application, there are a few types and options to consider.

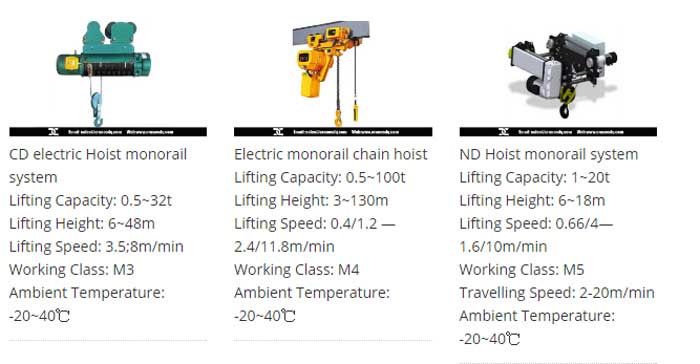

Hoist Type

There are two main crane hoist types, chain hoist and polipasto de cable. Chain hoists are typically used under 2 tons but 15 tons are available from some manufacturers. They are smaller, lighter, and offer a true vertical lift compared to a similar wire rope hoist.

A wire rope hoist is most typically used at a capacity over 2 tons and can range over 60 tons.

El poder

A monorail lifting system can be operated manually by a hand chain or a hand lever. A hand chain hoist has a chain that hangs down to the floor so the operator can pull the chain to lift and lower material. A hand lever hoist uses a ratcheting arm to lift or pull material. A manual hoist is not recommended for high capacity, high cycle applications.

An air powered hoist is good for hazardous environments and for general use. They offer throttled speed control for smooth, fast lifts. A control pendant will often be attached to the air hoist.

Electric hoists are most common, with units over 1 ton often requiring 3-phase AC power. Some hoists are capable of easily switching between 230 VAC and 460 VAC. A control pendant can be attached to the overhead hoist. Radio controls can replace the pendant.

Mounting

A hook mounted hoist can be mounted to a fixed location but it can also be relocated. Trollies are available that can hold a hook mounted hoist but most hoists can be supplied with special brackets specific for trolley mounting for a better high hook dimension. A push trolley is feasible for use up to 2 tons. A motorized trolley is best for heavy loads and frequent movement.

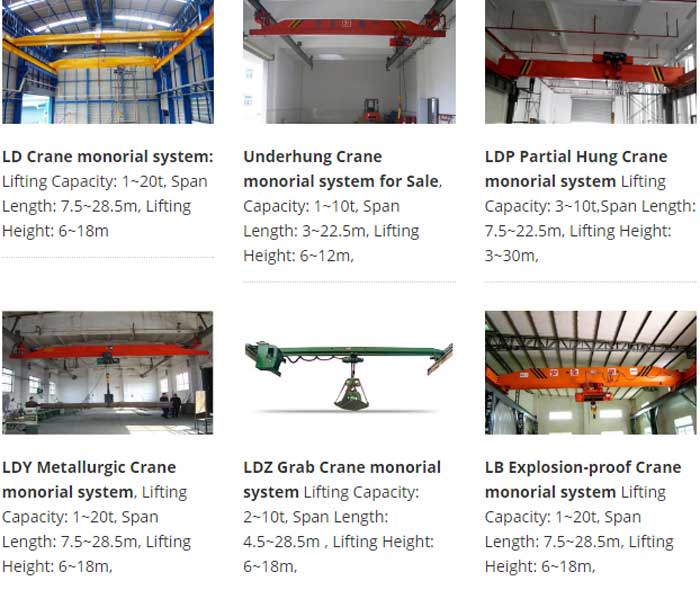

Overhead monorail system

Overhead monorail system and workstation cranes come in a variety of styles and are used with a number of attachments to facilitate load lift, including:

Monorails: A continuous run of fixed, overhead track on which carriers or trolleys—equipped with trolley hoists to lift, lower and suspend the load—travel. A series of carriers in a row is called a trolley conveyor. Hand trolleys are propelled manually; alternately, trolley movement can be by pneumatic- or electric-powered tractor drive, as is the case with an automated electrified monorail. Two types of track options exist:

Enclosed track – A rectangular tube-shaped track formed with a continuous slot running lengthwise along the underside of the section. Trolleys travel on the interior bottom flange of the track section.

Patented track – A composite track section fabricated to form an inverted “T” section that acts as the running flange for the trolley wheels.

Overhead conveyor: Similar to monorails, overhead conveyors consist of a continuous chain running beneath a continuous, stationary, flanged rail. Equally spaced, individual carriers are permanently suspended from, and pulled by, the chain. Power and free conveyor operates the same way, except the carriers can be mechanically disengaged for independent maneuvers.

Workstation crane: Generally used for ergonomic reasons to help workers perform tasks with less risk of injury, these cranes handle loads from 150 to 4,000 pounds. They allow workers to move materials by hand by pushing the load with the assistance of a vertical lifting device such as a hoist or other attachment. The three primary types include:

grúa de horca – Wall- or floor-mounted, jib cranes rotate off an axis and can move a load in a circular area, either 180° or 360°. A variety of types are available, depending on the mounting requirement to support the application:

• Column mounted

• Drop cantilevered

• Full cantilevered A form of wall mounted or column mounted jib crane that utilizes a vertical pivoted

• Wall traveling

• Wall mounted or bracket mounted

Bridge crane – For loading and unloading in assembly operations, these cranes are mounted overhead to a building’s columns, trusses or frames, or via a free- standing system of columns. They cover a rectangular area, moving a load side to side and backward and forward. The lifting and horizontal movement device is mounted on a bridge beam of one or more horizontal girders which are supported at either end by trucks. The end trucks are attached at right angles to the girders and move on fixed runways.

grúa de pórtico – Also called floor-supported or free-standing, the bridge for these cranes is supported on two or more legs running on fixed rails in the facility floor, or on wheels. A variety of types are available, depending on the configuration of the facility:

• Cantilevered

• Semigantry

• Single leg

• Double leg