grúa de arriba y grúa de pórtico electric control cabinet basics for your reference. Dongqi crane engineers help you learn more overhead crane electric control system and grúa de pórtico electric control system. Check now.

Crane electric system

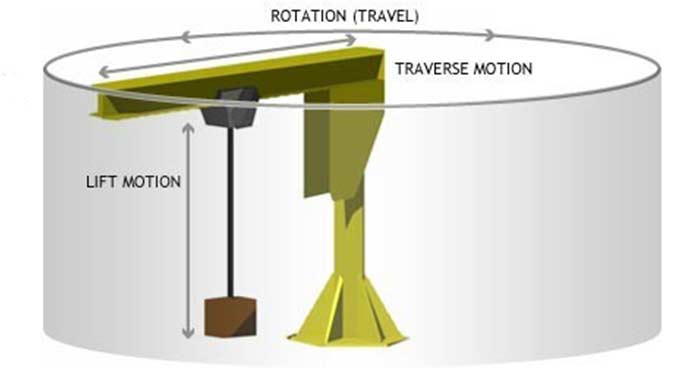

Crane steel structure responsible for load bearing; The crane is responsible for action; Crane body movements, such as starting, running, reversing and stop all are done by electrical or hydraulic control system, in order to crane movements smooth, accurate, safe and reliable operation is inseparable from the electric transmission, control and protection effectively.

ELECTRIC SYSTEM OF GANTRY CRANE

Crane electric drive

Crane to the requirement of electric drive speed regulation, smooth or rapid braking, rectifying, synchronized, coordination between agencies, hoisting check place, etc. Which speed is often as important requirement.

General crane speed control performance is poor, when need accurate stopping, the driver can only take control method of “point”, if “car” many times, not only increase the driver’s labor intensity, and because the number of electric power and electric motor starting number increase, and make the electrical appliances, motor greatly shorten the working life, more and more accidents in maintenance quantity increase.

Because most crane speed control should be carried out in the process of running, and change a lot, so the mechanical transmission is generally not very suitable, most need to use electrical control. Electric control of motor speed is divided into two broad categories: dc speed control and ac speed regulation.

Dc speed control has the following three options: fixed voltage power supply dc series motor, change the series resistance and the connection of dc speed regulation; Controllable voltage power supply dc generator – dc motor speed control; Power supply of thyristor controlled voltage power supply, dc motor of dc speed regulating system.

Dc speed control has a large overload capacity, speed, the braking performance is good, suitable for frequent braking and lower accident rates. The disadvantage is that system structure complex, expensive, require dc power supply, etc.

Ac speed regulation is divided into three categories: frequency conversion, slip ratio of the change pole, variable.

Frequency modulation speed control technology has been widely used to hoist the stepless speed regulation of operation of electronic variable voltage variable frequency speed regulation system of the subject – frequency converter for supply series products.

Speed regulating pole change motor is mainly used in the squirrel cage type double winding hoist crane on the change pole motor, the pole change motor logarithmic technique was used to realize speed regulation.

Variable slip velocity modulation way more, such as changing winding asynchronous motor series resistance method, rotor thyristor pulse speed regulation method, etc.

Besides the above speed double, hydraulic driver control of motor speed, motor speed pulse power braking control of motor speed, rotor speed, cochlear flow brake control of motor speed, the stator voltage regulation speed regulation and so on.

ELECTRIC SYSTEM OF OVERHEAD CRANE

Automatic control of crane

Programmable controller, program control device is composed of digital electronic control system, general program automatic control function is mainly composed of programmable controller to realize.

Automatic positioning device, automatic positioning of crane is generally based on the use of the controlled environment, the accuracy to determine the structure of device. Automatic positioning device usually use all kinds of detecting element and relay contactor or programmable controller, mutual cooperate to achieve the goal of automatic positioning.

Cart running mechanism of rectification and electrical synchronization – correction can be divided into artificial rectification and automatic correction. Human action is when the deviation exceeds a certain value, deflection signal generator signal, the driver to disconnect lead leg side of the motor, through to the side of the lagging leg motor to adjust. Automatic correction is that when the deviation exceeds a certain value, the rectification issue instructions command generator, automatic adjustment system. Electric synchronization is in ac drive, often used with balanced electrical axis of the motor system, implement electrical synchronization.

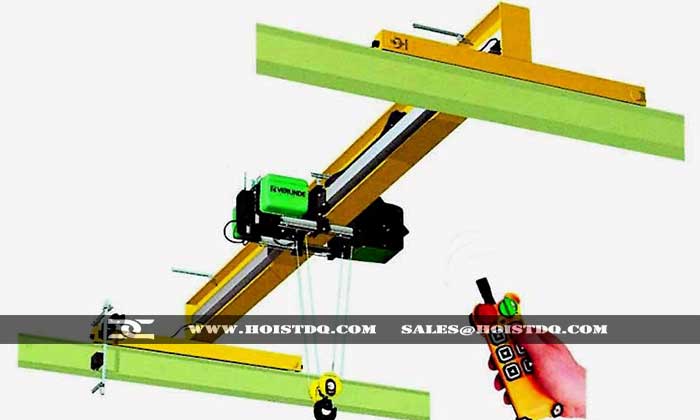

Ground controlling, wired and wireless remote control – ground controlling to hoist crane use more, its key components is manual push button switch, which is usually referred to the flashlight door. Cable remote control is through a dedicated cable or power line as carrier, the signal in modem transmission way, to use less channel control method can be realized. Wireless remote control is the use of modern electronic technology, the information in the form of waves or light for channel transmission to achieve the purpose of control.

ELECTRIC SYSTEM WITH SCHNEIDER BRAND OF DOUBLE GIRDER OVERHEAD CRANE

The power of the crane into the device

The power of the crane introduced device is divided into three categories: the hard soft slide wire power supply, power supply and cable electrical slip ring set.

Hard bare slip line power supply is introduced into the devices Angle steel flat collector, round steel (or copper) pulley collector and capacitor collector for power supply is introduced into sliding contact line.

Soft cable entry device the power of the power supply is used with insulating sheath core is made of soft wire, more flexible cable have two forms round and flat cable, they introduced by hanging power sports car power supply.

The crane electrical equipment and electrical circuits

Different types of crane is a variety of electric equipment, its electric circuit is different also, but the electric circuits of the largely consists of main circuit, control circuit, protection circuit, etc. Don’t have to be introduced here, only briefly introduce the typical product general eléctrico de la grúa bridge crane electric circuits of the main electrical equipment and basic.

Gm bridge crane electrical equipment

General bridge crane electrical equipment mainly include: motor, brake electromagnet agencies use, control and protection of electrical appliances.

Motor bridge crane agencies should use special lifting motor, it requires that has high mechanical strength and large overload capacity. The most widely used is wound rotor asynchronous motor, the motor adopts an external rotor resistance starting operation step by step, which can limit the starting current to ensure the smooth starting, and can provide enough starting torque, and can adapt to frequent starting, reverse, brake and stop the needs of the work. To demand higher capacity big occasion can use dc motor, small lifting weight cranes, sometimes USES the squirrel-cage motor running mechanism.

Protection of electric bridge crane protection appliances have cabinet, control panel, over-current relay, limit of the agencies, emergency switch, all kinds of safety interlock switch and fuse, etc. For the protection of electrical demand guarantee, safe and reliable work, ensure the crane safe operation.

The electric circuits of the crane

Main circuit directly drives the agencies said that part of the motor loop circuits. It is by the crane started sliding contact line, after the ark cabinet knife switch, protect contactor main contactor, repass agencies stator contactor to each corresponding motor, controller is composed of external electric motor stator loop and an external rotor circuit.

Control circuit of the control circuit of bridge crane is known as interlock protection circuit, which control the crane total power supply connected with the breaker, so as to realize all kinds of security and protection of crane. Crane is controlled by control loop total power on and off.

Lighting signal circuit Lighting signal circuit for the dedicated line, the power supply by the crane main circuit breaker of tapping into the line end, after the crane protection GuiZhu knife switch, lighting signal circuit still have electricity supply, to ensure that the downtime maintenance needs.