How to avoid key mistakes to get the best hoist equipment?

Purchasing a hoist that’s too slow for the operation.

- A slower speed means lower horse power and a cheaper price.

- The slower speed means it takes longer to do their job.

- Avoid this issue by checking the speed of the unit you’re replacing.

Buying a push trolley when a powered trolley is needed.

- When purchasing a trolley, here’s a general guideline: If an operator can safely push on the load at all times, then a push trolley will be fine.

- However, if the load is dangerous to handle, if there’s an opening in the floor, or if the operator needs to stand away from the load, then a motor-driven trolley is required.

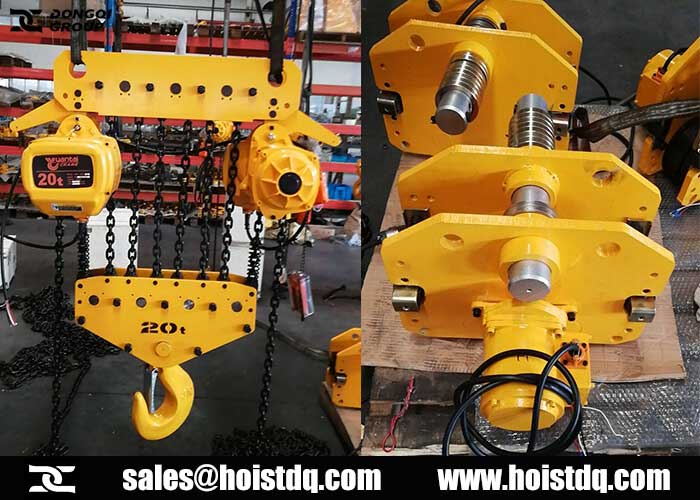

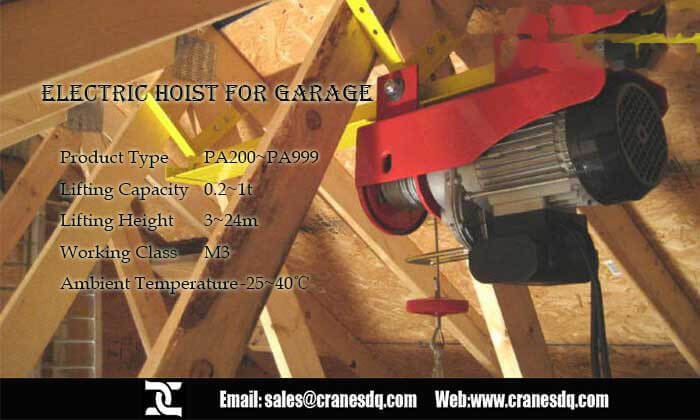

Buying a manual hoist for a long lift application.

- Manual hoists, units that lift and lower the load when the operator pulls the hand chain, are designed for relatively short heights.

- Any lift more than 6 meters really needs to be made by a powered hoist.

Purchasing a custom hoist with a finish unsuited for the environment.

- Hoists made standard by most manufacturers are finished with paint suitable for indoor use.

- If you need hoisting equipment for use outdoors or in an area where harsh chemicals are present, a special finish (for example – primer, finish coat, and/or urethane top coat) is well worth the extra cost for longer lasting equipment.

- No matter what, never purchase a custom hoist without any finish.

- Declining the paint charge might seem like a savings, but the unit will likely be rusted before it hits your factory floor.

Purchasing a standard electric hoist for a hazardous location.

- Hazardous locations are defined by the National Electric Code by Class, Group, and Division.

- Electric hoists and trolleys must be specially configured for the requirements of the particular application.

- Using a standard hoist in a hazardous location could cause a catastrophic accident.

Buying a single reeved hoist when true vertical lift is required.

- If you need the hoist to place an object precisely in one spot, then you need true vertical lift and double reeved wire rope hoist.

- Single reeved wire rope hoists are adequate for any application that doesn’t mind “hook drift’ – or, when the wire rope cable moves on and off the drum during the course of raising and lower the hook.

Purchasing a standard duty unit for a heavy duty cycle and trying to compensate with a higher capacity.

- Let’s say you have a 5 ton application where the hoist unit is used multiple times a day. It’s often rationalized that a 10 ton capacity hoist will be able to do the job since it can lift twice the load. However, this isn’t the case.

- To accommodate a high duty cycle, upgrade the hoist motor, the hoist brake and the controls.

- Specify heat treated sheaves and trolley wheels. Upgrades on a 5-ton capacity hoist will extend the operating life of the unit and save money overall.

Contact us for questions about standards hoists or specialty applications.