Background

DQCRANES, a leading material handling equipment supplier, recently designed and exported two 1 ton electric chain hoists to an assembly workshop in Italy. This project required a sophisticated synchronized lifting system using dual 1-ton electric chain hoists, equipped with a Single Transmitter Dual-Receiver wireless remote control system. The system was tailored to meet the client’s needs for precise, synchronized lifting operations in their assembly process.

Technical Challenges and Solutions

- Synchronization: Ensuring that both hoists lift and lower at the same rate and to the same height was a key challenge. DQCRANES addressed this by incorporating a sophisticated synchronization mechanism that ensures precise control of both hoists.

- Remote Control: The client required a wireless remote control system to allow for flexible operation of the hoists. DQCRANES provided a Single Transmitter Dual-Receiver system that allows for easy and reliable control of both hoists from a single device.

- Safety: Safety was a top priority for this project. DQCRANES incorporated a range of safety features, including overload protection, emergency stop buttons, and load monitoring systems, to ensure the safe operation of the hoists.

Project Details

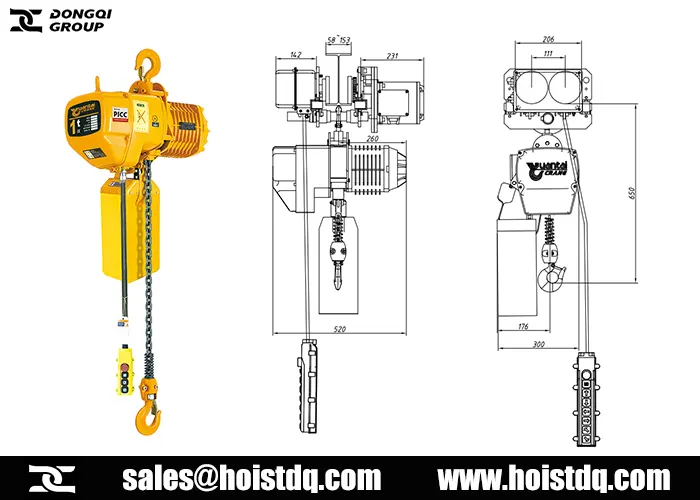

Electric Chain Hoist Specifications:

- Hoist Capacity: 1 ton each

- Number of Hoists: Two

- Lifting Height: 15 meters

- Lifting Speed: 6.8 meters per minute

- Control System: Single Transmitter Dual-Receiver wireless remote control

- Power Supply: 220V/50Hz/3phase

Synchronized Lifting System:

- The system utilizes two electric chain hoists with trolley that are synchronized to ensure precise and simultaneous lifting.

- The Single Transmitter Dual-Receiver wireless remote control allows for easy and efficient operation of both hoists from a single controller.

- This setup ensures that the loads are lifted and lowered in a balanced and controlled manner, minimizing the risk of misalignment or damage.

electric hoist with Remote Control:

- 8 single speed buttons, 1 start button

- Wide voltage design, low voltage version 24-264v, high voltage version 110-460v AC/DC universal

- Nylon+fiberglass material shell, resistant to pressure, impact, oil, corrosion, and not easily combustible

- Large emergency stop mushroom head button, compliant with European standards

- Built in antenna, effectively preventing accidental breakage of the antenna

- Remote control distance exceeding 100 meters, action response time less than 100 milliseconds

- 4.3 billion sets of SN codes and 100 sets of channel numbers, ensuring never repetition and preventing interference

- Built in automatic code matching function, which can automatically pair transmitters or receivers without a computer or copying machine

Button Function Description

- “Up”: Control the hoist to rise;

- “Down”: Control the descent of the hoist;

- Button 1 to 2: Can independently control the 2 hoists (Hoist No. 1, No. 2).

Operation:

- Press 1 to start No. 1 hoist, press the Up and Down button to operate hoisting, and press 1 again to cancel No. 1 hoist operate.

- Press 2 to start No. 2 hoist, press the Up and Down button to operate hoisting, and then press 2 again to cancel No. 2 hoist operate.

- Pressing 1 and 2 at the same time, the two hoists will be synchronous working.

Note: The interval between two consecutive buttons press should not be less than 1 second to avoid damage to the remote control.

The four buttons in the middle (East/West/South/North) are for spare use, if there is any button not good in use, then can change the wiring to the spare button.

Export and Installation

DQCRANES handled the entire export process, including customs clearance, shipping, and delivery to the client’s site in Italy.

Our technicians were also responsible for the online support to installing and commissioning the system, ensuring that it was fully operational and meeting the client’s requirements.

Client Feedback

The client was extremely satisfied with the system provided by DQCRANES.

“Very appreciated the high level of customization and technical support provided by DQCRANES. The synchronized lifting system of 1 ton electric hoist with remote control has significantly improved the efficiency and safety of the assembly process in our workshop.”

Result

- Improved Efficiency: The synchronized lifting system of dual electric chain hoists has streamlined the assembly process, reducing the time required to lift and position heavy components.

- Enhanced Safety: The system’s safety features, including overload protection and emergency stop buttons, have minimized the risk of accidents and injuries.

- Ease of Use: The Single Transmitter Dual-Receiver wireless remote control system has made it easy for operators to control both hoists simultaneously, reducing the complexity of the lifting process.

Electric Chain Hoists for Assembly Workshops

For assembly workshops, DQCRANES offers various types of electric chain hoists for sale available to meet different lifting and positioning needs. Here is a list of some common types of electric chain hoists used in such environments:

Single-speed hoists operate at a fixed speed, making them suitable for general-purpose applications in assembly workshops that involve repetitive lifting and lowering of loads. They are cost-effective and simple to operate, making them a popular choice for basic lifting needs.

- Dual-Speed Electric Chain Hoists

Dual-speed hoists provide greater flexibility by offering two operating speeds—one for faster lifting and another for slow, precise movements. This feature is particularly beneficial in assembly workshops where delicate positioning or alignment of components is required. The ability to switch between speeds enhances productivity while ensuring precision and safety.

Low-headroom electric chain hoists are designed with a compact structure that minimizes the distance between the hoist body and the load hook, allowing maximum use of the available headroom. They are commonly used in workshops with limited vertical space.

Trolley-mounted hoists combine lifting capabilities with horizontal movement along a beam or track. These hoists can be either manually operated or motorized, depending on the application. Trolley-mounted systems are perfect for assembly workshops where loads need to be transported across different workstations, offering both versatility and efficiency.

- Explosion-Proof Electric Chain Hoists

For workshops operating in hazardous environments with flammable gases or dust, explosion-proof electric chain hoists are essential. These hoists are specially designed to meet stringent safety standards, featuring components that prevent sparks or overheating. They ensure safe and reliable operation in industries such as chemical manufacturing or oil and gas.

When selecting an electric chain hoist for an assembly workshop, it is important to consider factors such as the weight and size of the loads, the available workspace, safety requirements, and the specific tasks that need to be performed.

DQCRANES’ commitment to innovation, customization, and technical support has earned them the trust and satisfaction of their clients. Contact DQCRANES to get an electric chain hoist that meets all the necessary criteria and is suitable for the intended application.