Introduce:

In today’s fast-paced manufacturing industry, optimizing productivity and ensuring employee safety are critical factors on any production floor. An effective solution to achieve these goals is to install a European standard monorail hoist. Recently DQCRANES offered a 3 ton monorail hoist successfully to meet the requirements of a production workshop in Benin. Hope this project will be helpful for your reference.

Customer Background:

Our client, a well-known production floor operator in Benin, sought to improve its material handling processes to increase productivity while prioritizing employee safety. They are particularly interested in replacing outdated lifting equipment with modern, reliable solutions that can withstand harsh operating environments.

Customer Requirements:

The customer required a heavy-duty lifting system that could easily lift to 3 tons. In addition, they wanted the system to comply with European safety standards to ensure their employees could operate the equipment safely. Meeting these requirements is critical to the success of its operations.

Our Monorail Hoist Solutions:

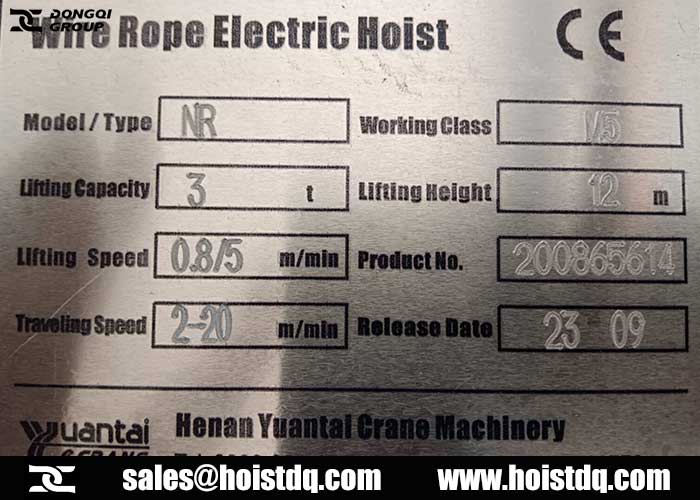

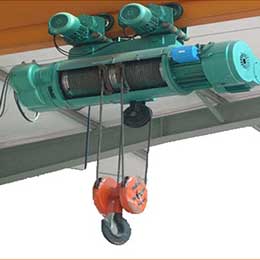

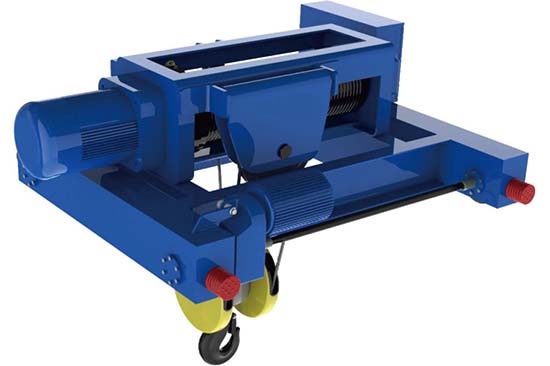

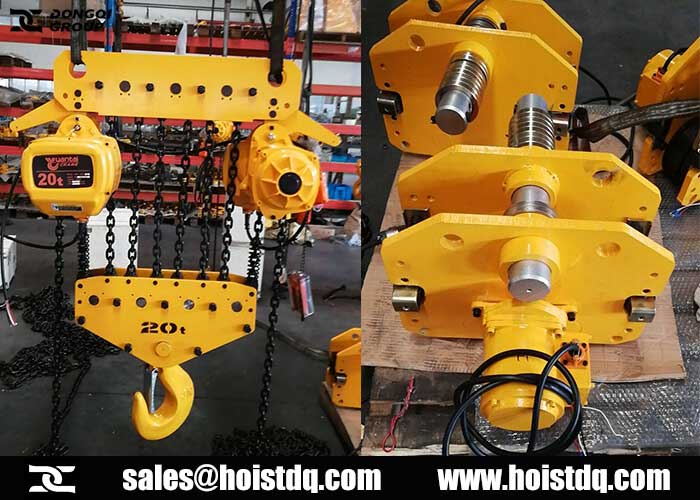

After understanding the customer’s specific needs, we recommended installing a European standard electric monorail hoist, a 3 ton wire rope hoist, to meet their material handling needs. This custom monorail hoist has a double lifting speed of 0.8/5.0m/min and offers many advantages, including its sturdy construction, reliability, and ability to handle heavy loads efficiently.

Technical Parameters:

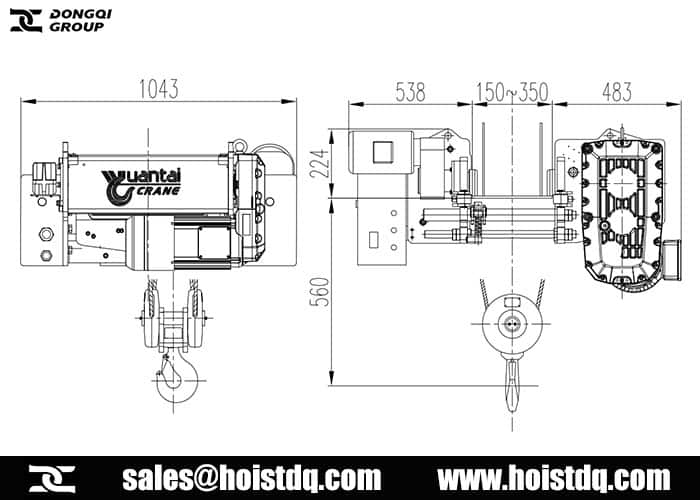

- Capacity: 3 tons

- Lift height: 12 meters

- Hoist lifting speed: 0.8/5.0 m/min

- Trolley speed: 2.0~20 m/min STEPLESS

- Lifting power: 0.45/3.2 kW

- Trolley motor power: 0.4 kW

- Power supply: 380V/3P/50Hz

- Lifting/Trolley group: FEM 2m (M5)

- Control method: Pendent control

- Working site: Indoor

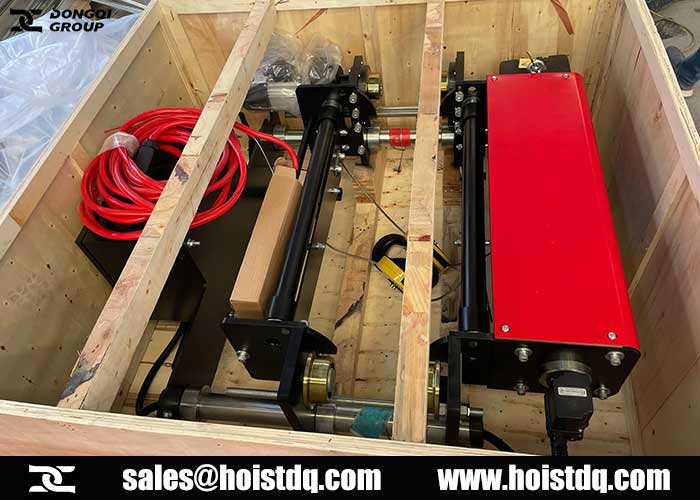

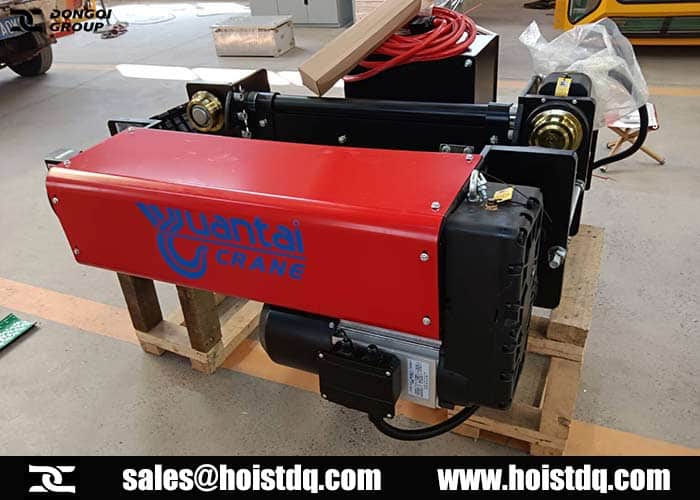

Production and Package:

Monorail Hoist Design Features:

- Robust structure: Monorail hoists are designed to withstand the rigorous demands of a production workshop environment. Its rugged and durable design ensures a long service life and minimizes maintenance costs.

- Accurate and stable operation: The hoist adopts advanced technology to ensure stable and accurate lifting, ensuring the safe transfer of heavy objects in the workshop. Using a wire rope hoist allows for greater flexibility and excellent load control.

- Enhanced safety measures: The monorail trolley hoist complies with strict European safety standards and includes features such as overload protection, emergency stop buttons and limit switches. These safety mechanisms protect the operator and the equipment itself.

- Adjustable lifting speed: The elevator provides adjustable lifting speed, allowing the operator to control the speed of material transfer according to his specific needs. This feature increases shop floor efficiency, reduces downtime and maximizes productivity.

- Easy to maintain: The hoist is designed for easy maintenance, allowing easy inspection and timely troubleshooting when needed. This minimizes the risk of unexpected failures and ensures uninterrupted operations.

Why Choose European Monorail Hoist?

- Improve production efficiency: The installation of the 3 ton monorail hoist simplifies the work process in the workshop. The ability to efficiently handle heavy loads combined with adjustable lift speeds helps increase productivity and reduce wasted time during material handling operations.

- Enhanced safety: Compliance with European safety standards significantly reduces potential risks associated with material lifting. Overload protection and other safety features ensure a safe working environment for operators, reducing the possibility of accidents.

- Cost-Effectiveness: The long service life and low maintenance requirements of the hoist reduce the total cost of ownership for the customer. The equipment’s durability and its ability to operate reliably under heavy loads means less downtime and less repair costs.

- Versatility: The design of the monorail electric hoist allows for flexible lifting of various materials in the workshop, adapting to different shapes, sizes and weights. This versatility allows our customers to efficiently adapt to different production requirements.

- Future expansion: As customer business grows, the 3-ton monorail hoist can be easily upgraded or expanded to meet increasing material handling needs. This scalability ensures the long-term value of customers’ investment.

In short, the Benin customer’s production workshop successfully installed a European standard 3-ton monorail hoist, which significantly improved the efficiency and safety of its material handling process.

The hoist’s user-friendly features, compliance with international safety standards, durability, and versatility provide numerous benefits to our customers. As a result, our customers experience increased productivity, enhanced safety measures, cost-efficiency in operations, and the ability to easily accommodate future expansion.